McMaster University researchers are working with a Toronto-based start-up to create a blood-testing device to help reduce the number of blood samples required from patients to get accurate results.

The partnership between ChroMedX and McMaster University has been awarded a $25,000 NSERC Engage grant, which are designed to foster research partnerships between academic researchers and industry.

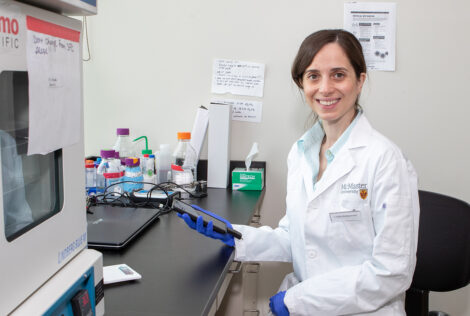

Ravi Selvaganapathy, an associate mechanical engineering professor at McMaster, is working with the biomedical company to help design and develop a process for production of the HemoPalm blood analyzer system.

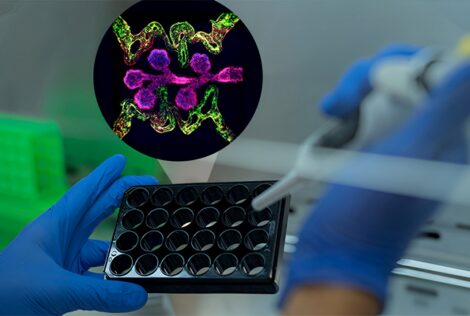

Current lab systems require blood samples to be run through two different types of analyses – electrical and optical – to test for abnormalities and diseases. ChroMedX’s aim is to to reduce the number of analyses required to one, which would decrease the number of vials of blood required from patients.

Selvaganapathy, the Canada Research Chair in Biomicrofluidics, is working with a team from the McMaster Manufacturing Research Institute (MMRI) to use tooling and processing techniques more commonly used in fields such as automotive, aerospace and steel and applying them to this ‘lab-on-a-chip’ project. The microfluidics expert, who explores how small amounts of fluid can be handled, will work on creating the small device so it channels blood properly and works consistently. One of the capabilities of MMRI – a research lab designed to assist manufacturers – is the large machines found in it can create intricate structures which move blood with precision and with finishes that do not damage the blood cells.

“Typically these techniques have been applied to automotive industries. We are adapting these techniques and applying them towards small-batch prototyping for the biomedical industry,” Selvaganapathy said.

Stephen Veldhius, the director of MMRI, said the new partnership is an opportunity for the institute to help a broader range of manufacturers. The goal is to help companies make “lab-on-a-chip” products that are more affordable and mass-produced.

“The challenge is trying to incorporate all the complexities into that chip and making it disposable,” Veldhuis said. “What Ravi is trying to come up with is the mechanism by which you manipulate the blood and expose it to reagents and assess it. If you can incorporate all of that in a very affordable package then you’ve got something a doctor can use as a diagnostic test right in the office.”

The MMRI is hosts an annual industry open house. For more information go to McMaster Manufacturing Forum website.