The McMaster University Student Centre was thrumming with energy as people visited booths to learn more about innovative biomedical engineering solutions to healthcare problems.

The event celebrated students of all year levels from McMaster University’s iBioMed program. There are two focus streams: the Bachelor of Engineering and Biomedical Engineering (BEng BME) or Honours Bachelor of Health Sciences in Health Engineering Science and Entrepreneurship (BHSc.)

Some of the students who came together and presented their work from individual courses, as well as capstone projects and theses, will be graduating as the first-ever cohort from iBioMed.

The showcase also featured those completing the first-year program — integrated biomedical engineering and health sciences — where students explore possible degree paths and build a foundation of math and science alongside a personal network of peers.

Here are some of the fantastic projects that were on display.

Engineering and Biomedical Engineering (BEng BME)

Rotator Rehab

Year 3

Mackenzie Keeler (BME + Mechatronics), Jordan Hoedt (BME + Chemical) Madelyn Hogan (BME + Engineering Physics) and Owen Johnstone (BME + Engineering Physics)

The Rotator Rehab device helps rehabilitate a patient throughout all the stages of their recovery from a rotator cuff injury.

It has three different modes: assessment, recovery, and the challenge mode.

Mackenzie Keeler explained that their approach ensures the device can be used to see how a patient is progressing over time. It’s also portable, allowing it to be used outside of a physiotherapist’s office.

“We were trying to come up with something that’s as accessible as possible and has the ability to be used as long as possible so patients don’t have to keep going back for more and more appointments. It’s a one-stop-shop for everything,” Keeler said.

The assessment mode quantifies the “drop arm test,” commonly used to diagnose a rotator cuff injury. The patient is required to lower their arm with control; if their muscles aren’t strong enough and the arm drops, the device detects it.

The recovery mode is for rehabilitation. There are four different levels, each increasing in difficulty to help build strength over time. The patient holds their arm to various angles, and a buzzer dictates whether to raise it higher or lower, depending on the sound’s frequency.

In the challenge mode, a second person attempts to push the patient’s arm down. If the patient is unable to resist and the arm goes too low, a buzzer will sound off. The Rotator Rehab will measure the maximum force and average force withstood.

Students not only brought their various engineering specializations to the table, but also communicated with doctors who have experience treating patients with rotator cuff injuries in order to design a device of clinical use.

DiTrack

Year 5, Capstone project

Jaclyn Winitsky (BME + Engineering Physics), Arjun Jagota (BME + Engineering Physics), Justin Prez (BME + Software), Harshil Modi (BME + Software)

DiTrack is a diet tracking application that integrates itself with a Bluetooth powered scale, which is designed to help those with gastrointestinal disorders.

The issue in the clinic, Jaclyn Winitsky said, is that while physicians want specific information on the type, amount, and timing of food consumed, patients often can’t recall the details.

“What we’re seeing with already existing solutions is that they often come with memory reliance, or they’re very time-consuming, or there’s poor accuracy,” Winitsky said. “We needed to make something that was really simple and didn’t rely on memory.”

That’s where DiTrack comes in. The user opens the application on their personal device, places food on the scale and snaps a photo. They are able to write a brief description and press a button on the scale for the weight. The food element is added to a diary, which serves as a log of meals and tracks the diet over time.

Users can generate a report for their physician that covers the time period required.

Future additions, Winitsky explained, would ideally incorporate machine learning to quantify the calories, macronutrients, and protein in all the meals.

The students went through a McMaster Research Ethics Board approval process and recruited participants to use the application.

“It was really rewarding to see it in action. People have downloaded it from the application store, and they said that it was really great and user-friendly. We’ve taken that feedback and they’ve given us some constructive criticism as well to be able to improve it for the future.”

Integrated Biomedical Engineering and Health Sciences (IBEHS 1)

The following projects were created as part of course 1P10 Health Solutions Design Projects, which also covers topics in ethics and professionalism, health and safety, communication, visualization, computation, and materials.

Comfort Cosmetics: finding beauty in accessibility

Year 1

Saakshi Arvikar, Yasameen Ihsan, Derron Li, Shane Golden

Comfort Cosmetics is a muti-functional makeup kit designed to improve accessibility and ease of makeup applications for those with multiple sclerosis (MS.)

This group’s client stressed her preference to apply makeup without a tool that would be fully automated.

“The device is designed to support the client and help her apply makeup, but she’s still able to feel independent and comfortable, which is really important,” Shane Golden said.

It’s also significant as MS patients need to continue use of their muscles to keep up their strength.

The makeup brush has a large, rounded, ergonomic grip, which reduces the amount of pressure needed to hold it. The brush is equipped with a miniature DC motor, allowing it to spin and pulsate and eliminating the need for repetitive brushing motions.

A palette-opening clip is incorporated into the brush’s handle, which can easily pop open containers and compacts. Since the client uses one hand when applying makeup, the kit includes compartments with non-slip, silicone mats, which are fit for the standard size of various makeup products. This allows the client to place a product and twist open a cap.

The students noted that the client expressed how difficulties with applying makeup affected her self-esteem and confidence. As MS is diagnosed more commonly in women between ages of 20 to 40, Golden said, a kit would assist those who also fall within the demographic of those purchasing beauty products.

They also noted that the product could be used by anyone with limited motor skills.

Roll-X

Year 1

Ursula Chui, Clara Curic, Matthew Siracusa, Devin Wang

The Roll-X is an attachable two-directional ratchet to a wheelchair, which is designed to assist a client with MS to operate their device without full automation.

The students explained that their client experiences spasticity in the right side of her body, affecting her grip, and wished to control her wheelchair with two hands.

“We wanted to find a way we could do it without a device that actuates the task,” said Ursula Chui.

The first component of Roll-X includes a detachable handle with a strap and sponge ball that the client can hold; this handle slides into place on the mechanism. It’s also adjustable, meaning that if the client’s hand is stiff and curled, she can still operate the ratchet.

An electronic switch powers a motor that controls the direction that the two-directional ratchet propels the wheelchair. This allows the wheelchair to move both backwards and forwards.

The ratchet doesn’t require re-gripping and replicates the way the client is moving her wheelchair now. The client’s hand is still able to return to the top of the wheel without causing the wheelchair to move.

“The client wanted something she could use on a daily basis without re-learning a new motion. That was what inspired this idea,” Clara Curic said.

The Walk N’Roll, a 2-in-1 walker/wheelchair

Year 1

Thomas Kells, Mathew Galuszka, Zara Khan, Anjali Kosuri

The Walk N’Roll combines a walker and wheelchair into one device. While walker-wheelchairs are available on the market, the students explained, the hybrid devices don’t have full functionality, meaning that their client and his wife often carry two mobility devices when they leave the house.

As the students collected information for their design, they were inspired by how the duo approaches life as a team.

“The four of us came to the consensus that since the client and his wife have a very strong dynamic, we wanted to make it easier for the both of them,” Thomas Kells said.

The Walk N’Roll prototype has larger wheels at the back to accommodate tough terrain, while smaller ones at the front allow for precise movements. The wheelchair is comfortable and accommodates a wide range of body weights.

When the students presented their device, which they handmade, on stage at the showcase, their client and his wife were in the crowd.

“We’re presenting along Capstone projects and thesis projects. To be up there as a first-year student and get to show off our work…it’s great to be able to showcase to other people what we spent a month-and-a-half on,” Mathew Galuszka said.

“It’s nice going through the process being able to actually talk to the person you’re building something for and then in the end, be able to present it to them.”

Health Sciences in Health Engineering Science and Entrepreneurship (HESE)

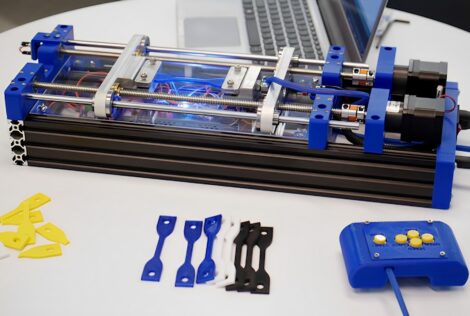

Assembly and Operation of the BioFilm Reactor

Year 5, Thesis Project

Konrad Grala

This CDC BioFilm Reactor will be at the centre of biofilm research at McMaster, and Konrad Grala’s efforts are behind its functionality.

Grala’s thesis project focused on assembling the reactor and ensuring it would be operational for the Hosseinidoust Lab – run by principal investigator and Grala’s supervisor Zeinab Hosseinidoust, an assistant professor in both chemical engineering and the school of biomedical engineering, as well as a Canada Research Chair in Bacteriophage Bioengineering.

Currently, biofilms are grown on 96-well plates. Grala explained that the method is not only time-consuming and costly, but it also results in biofilms that are separate “multicellular communities” and prone to differences.

That’s contrary to reality, where bacteria share traits – like antibiotic resistance – with the rest of the biofilm, resulting in increased strength and resistance. Using the reactor is a move toward increasing accuracy for life-saving research.

“When you have implants or other materials that enter the body, biofilms are very likely to grow and cause infections. Biofilms are one of the leading causes of infection in hospitals,” Grala said.

“That is why this reactor is a very important tool for research.”

Grala was responsible for troubleshooting, debugging and creating essential protocols – such as measures for sterilization – so that graduate students will be able to use the machine for their own research.

Bacteria is poured into the tank and given time to adhere onto the small discs called coupons. Over the time of the experiment – 24 or 48 hours – fresh media flow into the tank while waste media exits, and the biofilms grow. When the experiment is complete, coupons and the bacteria can be analysed for research, e.g. for therapeutic intervention.

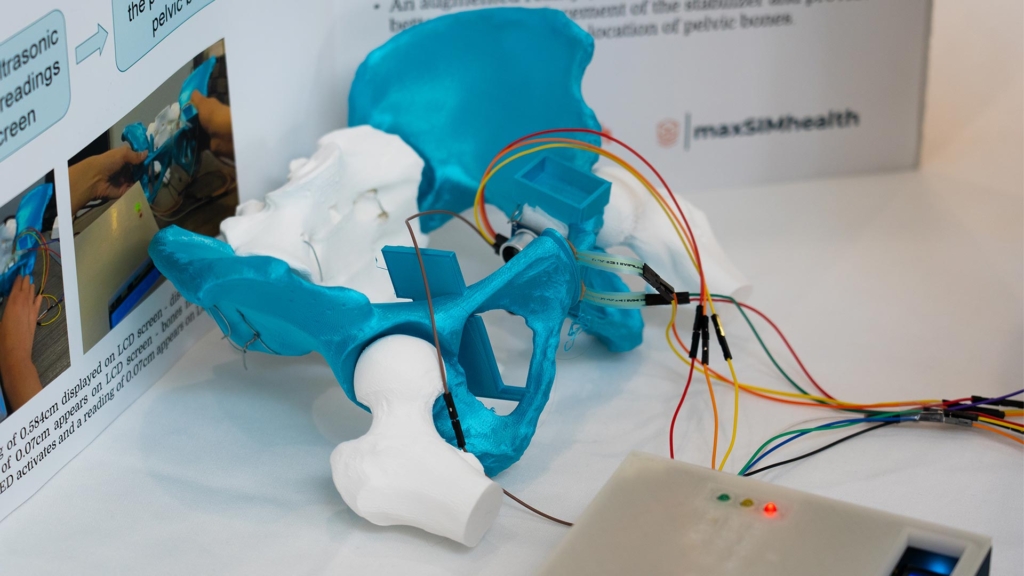

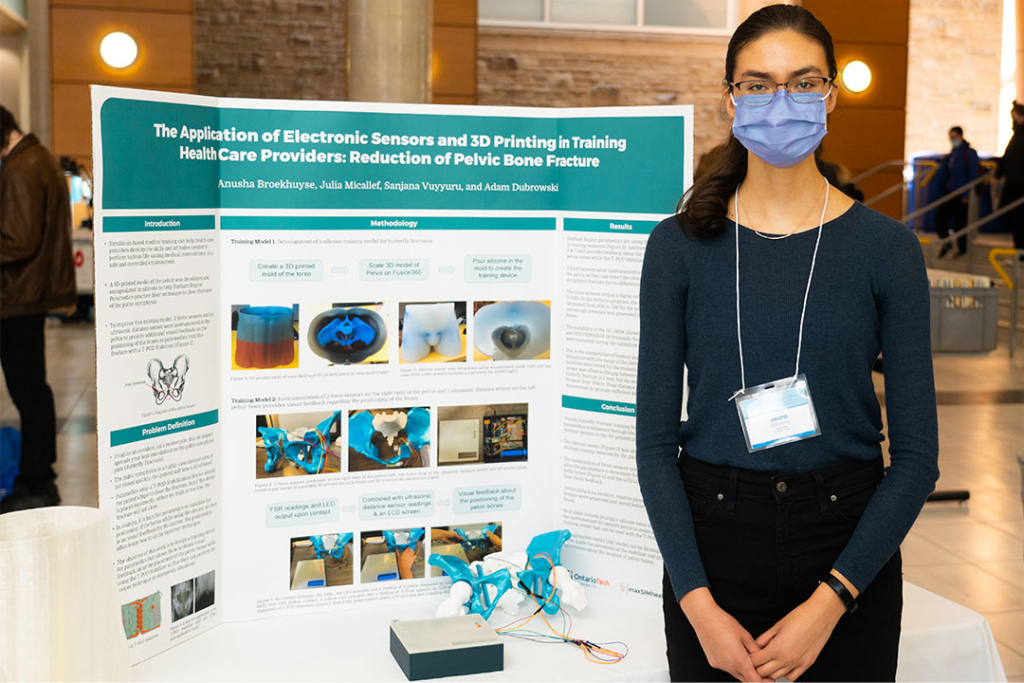

The Application of Electronic Sensors and 3D-Printing in Training Healthcare Providers: Reduction of Pelvic Bone Fracture

Year 3

Anusha Broekhuyse

This individual research project used electronic sensors and 3D printing to create two simulation-based medical training devices to help paramedics develop the skills needed to perform life-saving medical interventions.

The training devices are geared towards helping paramedics practice their application of a T-POD stabilizer, a device used to close butterfly fractures treated on the scene of motor vehicle accidents. The impact of such an accident spreads the victim’s legs apart and results in a pubic symphysis fracture and significant blood loss.

Paramedics handle these injuries by using a T-POD stabilizer that wraps around the victim’s hips to close the fracture. But, incorrect placement of the stabilizer, with respect to the hips, can have life-threatening consequences if the fracture is not completely closed.

Anusha Broekhuyse’s first training model is a 3D printed pelvis encapsulated in silicone, which provides visual feedback on the positioning of the pubic bones as the fracture closes while the stabilizer is in use. This training model is currently in use with the Region of Durham Paramedic Services.

The second model she developed uses two force sensors instrumented on the pubic symphysis and an ultrasonic distance sensor offset behind the symphysis. If both pelvic bones make contact with the force sensors while the T-POD stabilizer is in use, a green LED will blink. If only one force sensor makes contact, a yellow LED will blink and if no force sensors are activated, a red LED will blink, indicating misalignment of the pelvic bones and that the fracture is not closed.

The ultrasonic distance sensor provides real-time information on the distance between the pubic bones and the results are displayed on an LCD screen. Broekhuyse plans to further develop this model and give it to paramedics so that it can be used to enhance their training.

“Being in iBioMed, I really liked the engineering and health sciences. So, merging the two of them together, I enjoy using my skills in 3D printing and programming in order to make a difference in the healthcare setting,” Broekhuyse said.

A Gamified Approach to Learning Business Strategies

Year 5, Capstone project

Eugene Wu

As Eugene Wu nears his convocation, he’s dedicated his capstone project to augmenting the experience of future students by using gaming as a vehicle for knowledge.

His project objective was to make learning business and other entrepreneurship-knowledge more engaging.

“If you love playing games with your family and friends, why wouldn’t you do it at school as well?” Wu said. “You get that entertainment, and you get that knowledge and learning at the same time.”

Wu designed prototypes of games, rules on movement, scoring and trading, and a legend for gameplay. He also developed focus group questions to evaluate how students felt while playing and the key takeaways from the experience.

Supervised by Kenneth Owen, assistant professor in the department of medicine, division of education and innovation, Wu researched mechanisms used in popular, successful board games, such as dice rolls, simulations and board shapes, in order to make the game and learning process more effective. The content of the game can be altered according to lecture material that students need to learn.

Future development, Wu said, could include collaboration with engineers to code a digital platform for the game.