On August 11th, McMaster Society for Engineering Research (MacSER) and Engineering Co-Op & Career Services (ECCS) hosted its fifth Annual Undergraduate Research Showcase.

Over 100 students, staff, faculty and community members gathered in the John Hodgins Engineering Building lobby to get a taste of research and ice cream as they chatted with student researchers.

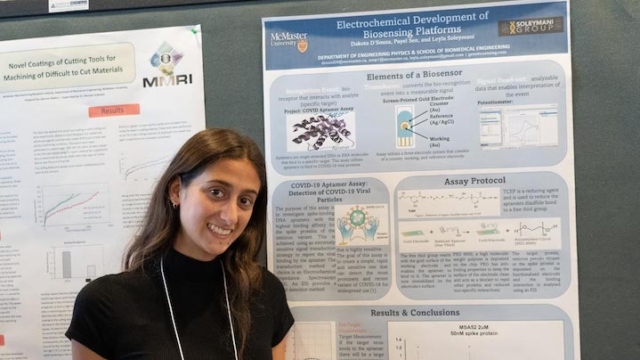

There were over 50 poster presentations on research areas such as the ethics of artificial intelligence and data collection, characterization of bone structure, electrochemical biosensing, zinc ion batteries and more.

McMaster Engineering has one of the largest undergraduate research programs in Canada.

Many of the students had the opportunity to undertake ground-breaking research through support from the Engineering Research Experience Award, which is jointly funded by the Faculty and Natural Sciences and Engineering Research Council of Canada (NSERC).

Discover a sample of some of the research conducted by our Mac Eng students.

Food Packaging Suitability of Biodegradable Polymer

Abigail Richardson, Mechanical

Supervisor: Dr. Li Xi

Tell me about your project.

This summer I have been researching biodegradable polymers. Our goal is to find biodegradable alternatives for food packaging. My project specifically focused on testing the hydrophobicity (water repelling properties) of biodegradable polymers. I did this mainly by testing water absorption and water contact angle; two methods that help to give a better idea of how the polymers will behave in both long and short term packaging applications.

Describe a challenge you’ve faced in your research.

Throughout my research the main challenge that I faced was timing and preparation. In order to get the most accurate results I started every water absorption test on a Monday and checked them the following days at the exact time. This meant that I had to have all my samples prepared the week prior or I would be set back an entire week! Overall challenges within biodegradable packaging alternatives come into play with investors in the industry having a desire to create and implement these changes.

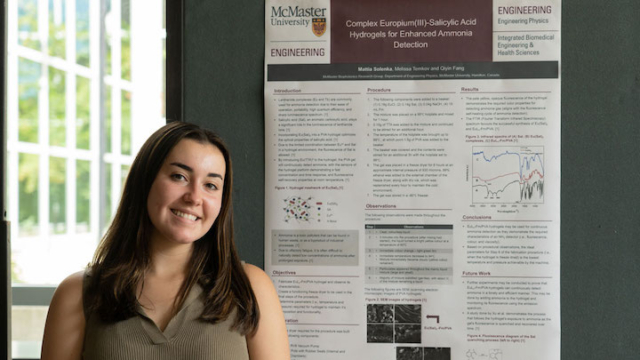

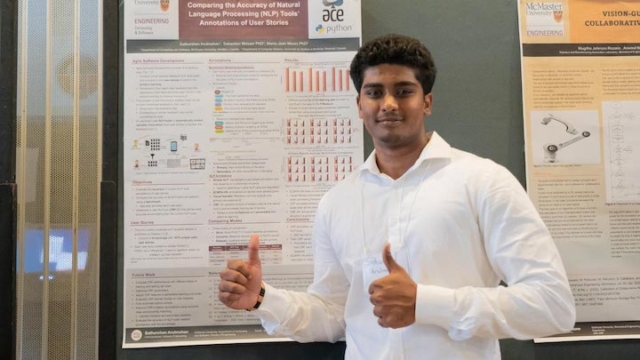

Comparing the Accuracy of Natural Language Processing (NLP) Tools’ Annotations of User Stories

Sathurshan Arulmohan, Software, Schulich Leader

Supervisor: Dr. Sébastien Mosser

Tell me about your project.

My project evaluates and compares the accuracy of NLP (natural language processing) tools’ annotations of user stories in Agile software development. Agile software development is a loop of receiving app feedback from customers and implementing it. This is helpful to extract valuable information from user feedback to summarize, group, and combine in order to shorten the feedback loop and provide efficient project flow.

What are some next steps in your research area?

Next steps would be to evaluate the current NLP tools’ performance on different datasets and scenarios outside of the Agile software development field. For example, how would the NLP tools perform on annotating Aviation messages.

Utilizing Slag (Steel production by-product) for sustainable construction applications (roads, buildings)

Student: Halima Banuso, Materials & Society

Supervisor: Dr. Leili Tafaghodi

Tell me about your project.

This summer, I had the pleasure to work alongside Dr. Tafaghodi and Dr. Dogan on a project surrounding the sustainable repurposing of Ferrochromium Slag. Slag is a by-product of ferrochrome metal production, with over 12 million tonnes produced globally; a year. It is often dumped in a landfill, which generates waste deposits. The focus of this project is to repurpose the ferrochromium slag as a sustainable aggregate for road and building construction while limiting the possibility of chromium in the slag leaching into the environment.

What are some next steps in your research area?

Going into the next steps of this project, we will conduct further experiments at different temperatures and cooling rates based on the preliminary calculations; I ran previously. In addition, we will analyze the surface of the experiment samples with a microscope to observe any inclusions.

Describe a challenge you’ve faced in your research.

A challenge I faced was getting myself up to speed with terminology; I was unfamiliar with and learning how to perform calculations using the Thermodynamic-Equilibrium Database. Thankfully, I had a great group of supervisors assisting me through every step.

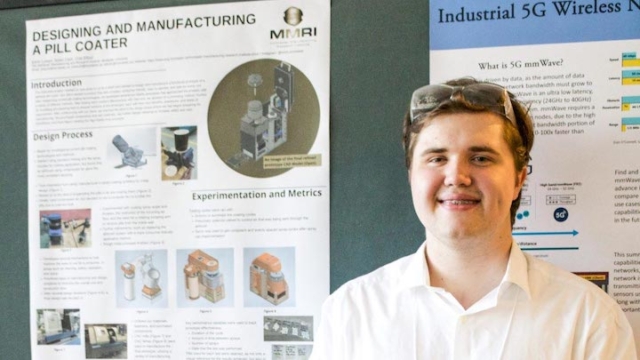

Client-based Project work in a manufacturing environment

Nolan Clark, Mechanical & Management

Supervisor: Kevin Lytwyn

Tell me about your project.

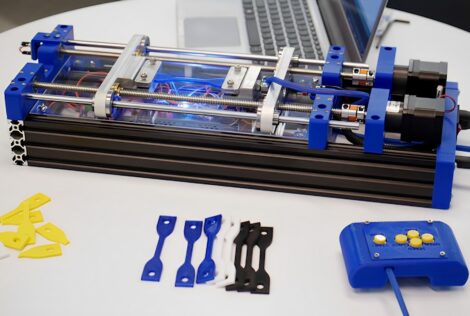

The project that I worked on during my internship at the McMaster Manufacturing Research Institute (MMRI) was given to the MMRI by a client who wanted us to design and fabricate a functional prototype of a commercial pill coater. Our client envisioned a product; that was compact, consumer-friendly, easy to operate and clean and safe for home use. We began by researching current pill coating technologies, and after gathering several promising concepts, we developed; and 3D printed several low-fidelity prototypes. After testing each model’s effectiveness with trial runs, we decided on a favourable method of tumbling pills into the air; and spraying them with a coating. Further, 3D modelling and planning – lead us to create several more versions of this prototype, each with its own benefits, drawbacks, and areas of improvement. After conferencing several times with our client, we purchased components and raw materials, had further design meetings to increase safety and user-friendliness, and have begun manufacturing the high-fidelity final prototype.

Describe a challenge you’ve faced in your research.

I am a first-year student, and apart from some general manufacturing experience in high school and the programming/design knowledge I’ve gained in my first year, I began this project with a fundamental understanding of design and manufacturing. At first, It was daunting to work with such powerful and complex CNC machines. However, thanks to the guidance; and excellent mentorship from supervisors, I gained valuable first-hand experience with industry-grade CNC mills and lathes and familiarized myself with complex machining techniques. I also received invaluable advice on properly designing projects for the manufacturing process, optimizing manufacturing processes, and avoiding excessively complex manufacturing techniques.