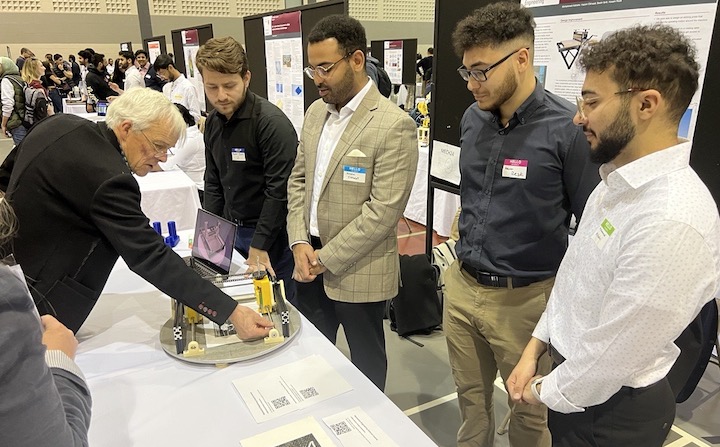

On April 11, 240 groups of McMaster engineering students in their final undergraduate year gathered at David Braley Athletic Centre to show off their final Capstone Projects; a culmination of years of hard work to find engineering solutions to address real world issues.

Here is a look at five projects from this year’s showcase that ranged from a material testing device to a hugging robot, an autonomous snowblower, a containerized water treatment plant and an accessible printing press.

Stress Labs

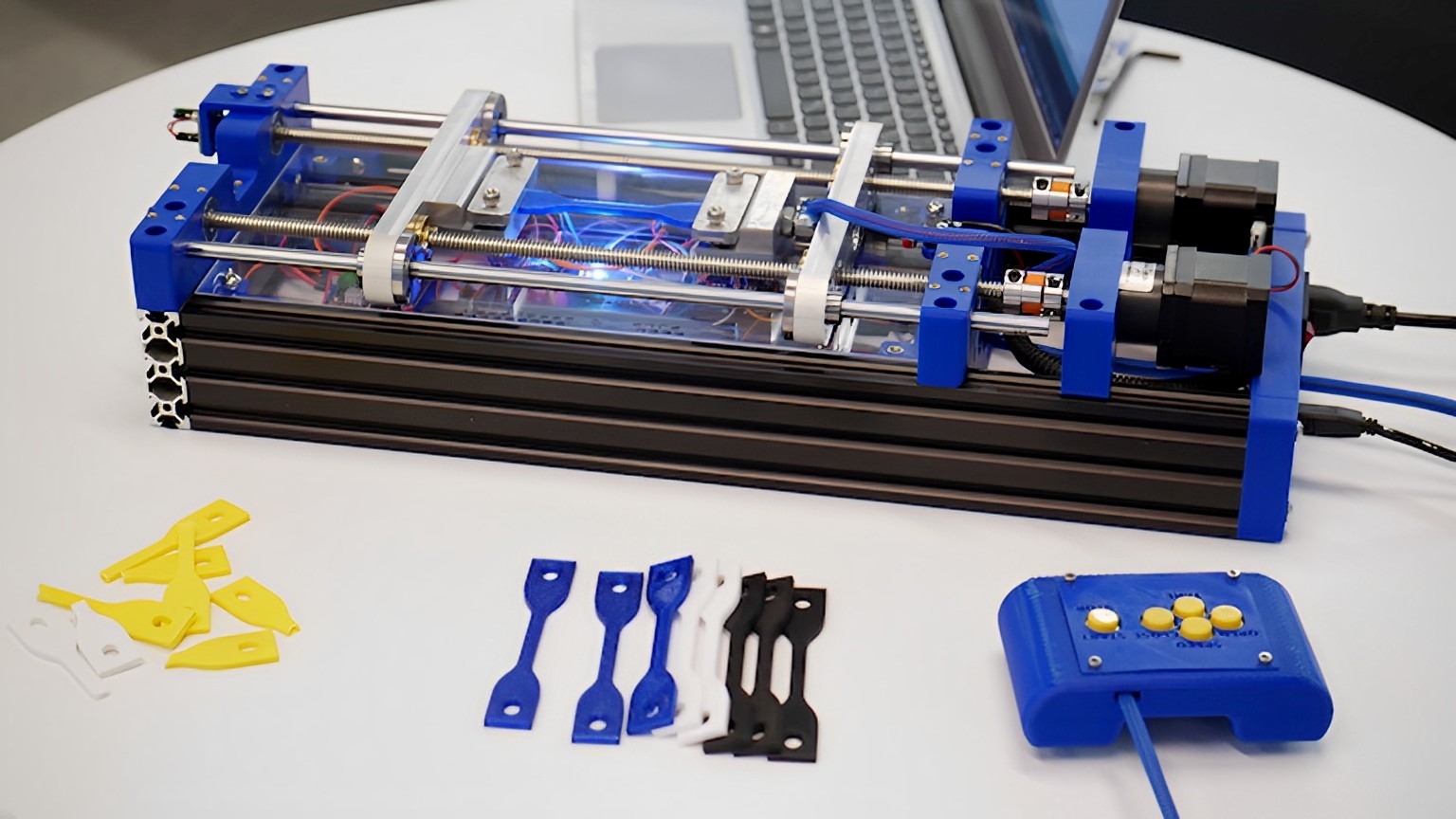

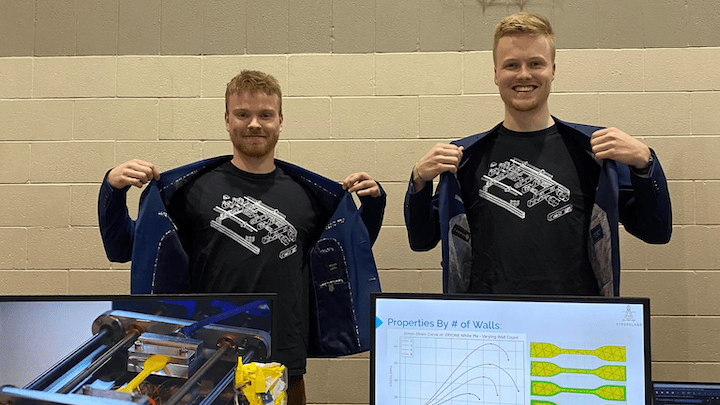

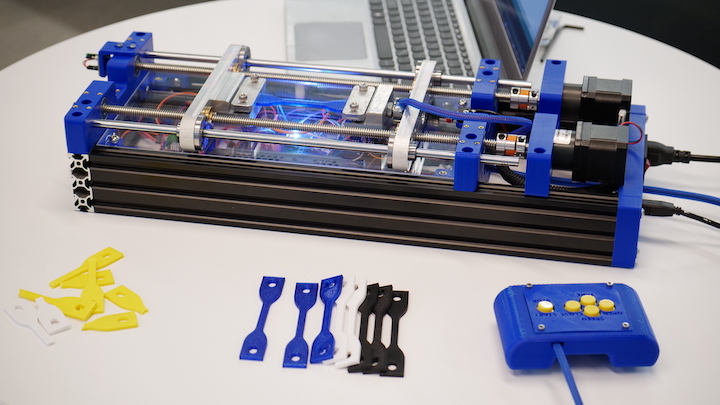

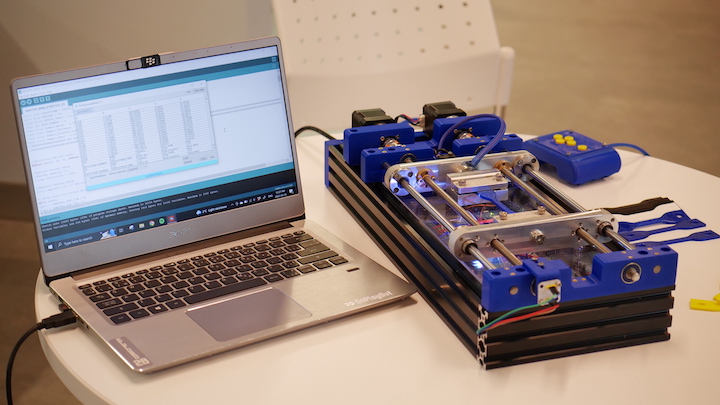

Product Name: Stretch 1.0

Group Members: Cole Elford and Oliver Kiessling

Stretch 1.0 is a low-cost, accessible, desktop tensile tester for low-strength materials [< 3kN]. It allows researchers, engineers, hobbyists, and students alike to determine key material properties of the exact materials they are designing with. Stretch 1.0 brings the world of material science to your workshop allowing for a data-driven solution to the 3D printing design process.

By designing a material testing device costing less than $1,000, Elford and Kiessling hope to create new markets for individuals who never had access to the insights provided by a tensile tester. With 3D printing becoming increasingly popular for engineering design and prototyping, Stretch 1.0 shines a light on the properties of the materials that designers are using removing the guesswork from the design process.

“Overall, this capstone project was extremely rewarding, as we were able to learn so many new skills in this fully integrated design and build,” says Elford. “From applying mechanical analysis learned in courses such as 3E05 and 3A03, to complete electrical design and finally software design (Arduino & Python). This project has been an idea we wanted to pursue since third year, and we are very thankful to have the support of the faculty to pursue this idea.”

Elford and Kiessling were the co-winners for Best Project and the recipients of the Best Use of Mechanical Design award. The team credits the hands-on learning opportunities throughout their time as Mac Eng students for their success in executing this project.

“Project-based courses such as Engineering Profession & Practice (1P03), Mechanical Engineering Design Theory and Project II (3E05) and Mechanical Engineering Capstone design project (4M06) encourage you to learn skills that are not taught in a classroom and are the most engaging as they give the opportunity to engage in hands-on learning,” says Kiessling. “Real-world application of mechanics, integration of mechanical and electrical design, active problem solving & group dynamics are all skills that are developed and practiced in project-based courses. Stretch 1.0 is tangible evidence of the skills we have developed over our undergrads and helps show our values as innovators and future Engineers.”

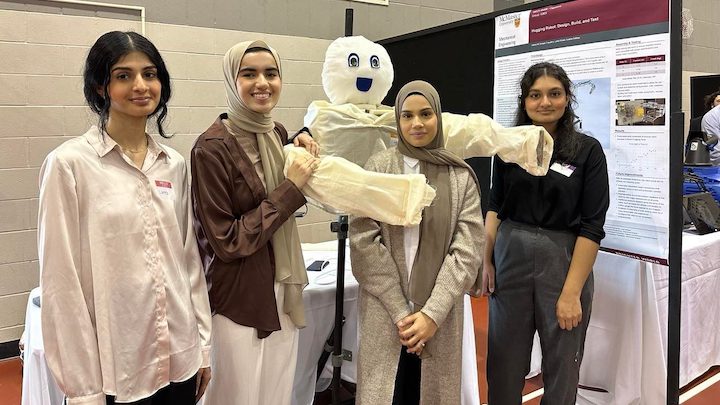

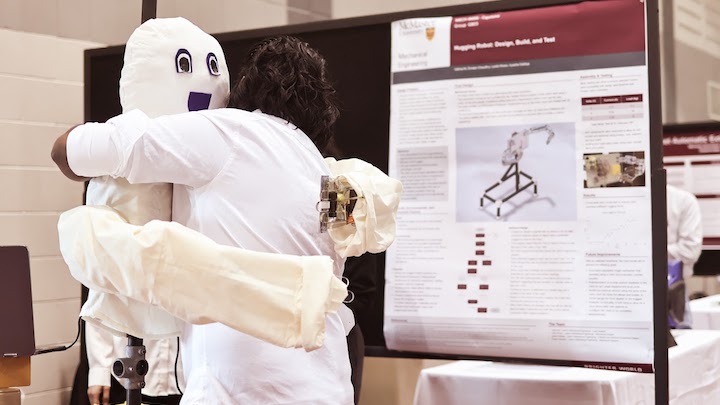

GB03

Product name: Hugging Robot (Hugsie)

Group members: Emaan Chaudhry, Lareb Khoso, Ushna Ali, Ayesha Siddiqa

Project conceived and supervised by: Dr. Gary Bone

Many individuals struggled with social isolation and mental health issues during the COVID-19 pandemic. The objective of this project was to design, build, and test a robot that could safely provide the aspect of physical touch and affection to users by replicating a human hug without requiring human contact. By fulfilling the human need for physical touch and affection, this hugging robot could contribute to the physical and emotional well-being of its users.

Hugsie is a robot that could be leveraged in a healthcare or other settings where the primary user is immunocompromised or has health conditions that require minimized social contact. A product like this could help individuals feel supported and comforted in times of solitude. Although many of us have resumed our lives in a post-pandemic world, this is not a reality for everyone. The hope of the group is that a product like this could help support the physical and emotional well-being of these individuals while also highlighting the importance of affection and physical contact.

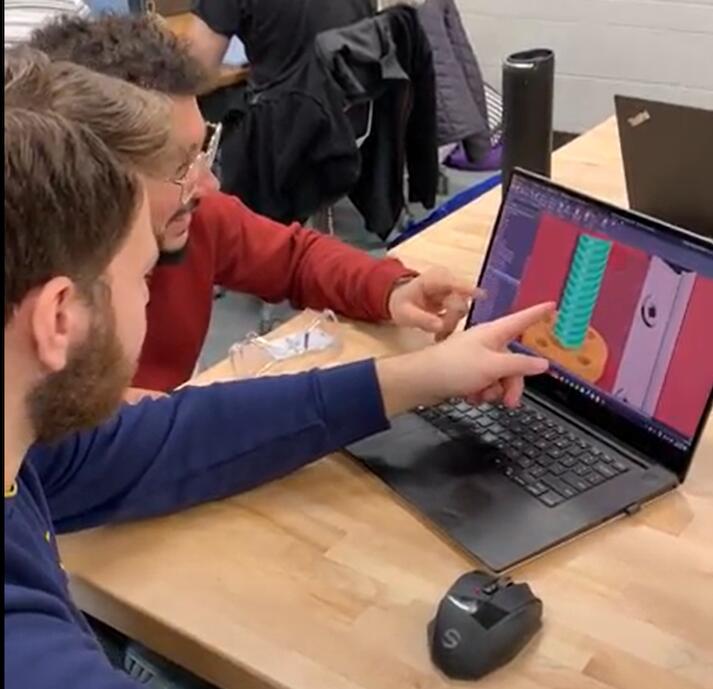

“This project gave us the opportunity to work through the entire project lifecycle, from research and conceptualization to building and testing,” says Chaudhry. “Not only did we get to research different actuators and existing robot designs, we got to see our design concept come to life, making for a much more holistic project experience. The design involved uncertainties, calculations, CAD modelling, part design, fabrication, machining, and assembly, giving our group the chance to explore several different aspects of mechanical engineering and see how everything comes together to create the final product. Although challenging, it was a rewarding and insightful experience.”

“The engineering program at McMaster provides the opportunity to explore core areas of engineering, from theory to building,” continues Chaudhry. “Mechanical engineering in particular gives you exposure to a breadth of subject areas, including mechanical design, thermofluids and energy, and real-life applications in laboratory settings. Our courses have pushed us to critically assess problems, break them down into simpler components, and generate solutions. Instructors provide resources and guidance, but encourage students to arrive at solutions independently, fostering critical thinking capabilities. We have found our most impactful learning experiences to be those in which we explored different avenues and generated solutions ourselves, tying together concepts we picked up over the years.”

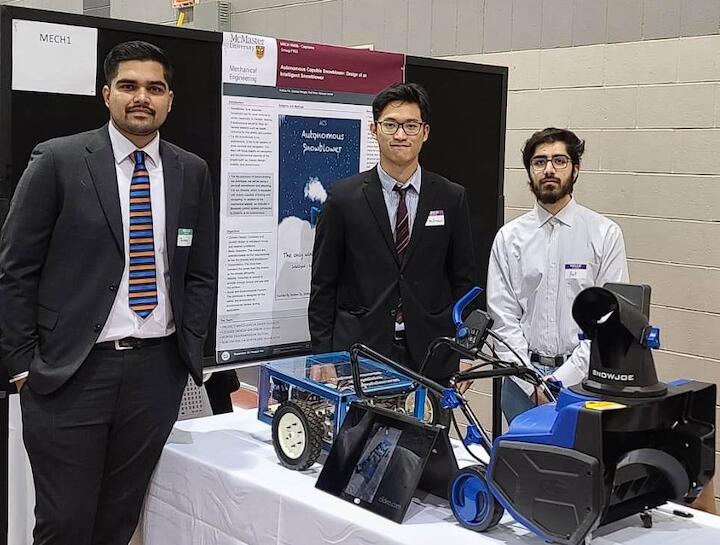

FY03

Product Name: Autonomous Snowblower

Group Members: Andrew Oo, Jaideep Mangat, Raif Khan, and Saroosh Ashraf

Project conceived and supervised by: Dr. Fengjun Yan

This autonomous snowblower serves as a device that can harness the capabilities of today’s artificial intelligence hardware & software to fully autonomize the process of clearing snow. The project utilizes a combination of mechanical, hardware, and software principles to maximize mobility and adaptability.

The opportunities to make real-world impact are endless with this snowblower and includes:

- Reducing the risk of heart attacks from the physical constraint from shovelling.

- Providing a viable option for snow removal to differently abled people, including those with physical disabilities.

- Reducing the need for heavy salt on driveways and salt run off that could contaminate water.

- Reducing the amount of gas powered snowblowers and pollution.

- Eliminating the risk of injury from snowblower accidents.

“This capstone project allowed our group to get an idea of what it truly means to be an engineer – from conceptualization to launch,” says Ashraf. “The atmosphere of the project almost felt like we were manning a start-up; pitching our idea, hosting design meetings, and adjusting to unforeseen challenges. The experience was extremely memorable, one that I know my group members and I will carry with the rest of our lives.”

Mangat also reflects on the incredible learning opportunity working on this project has provided him and his team.

“I really feel like I was given all the necessary tools and information to succeed as a student. During this capstone project, the technical staff in the machine shop and design studio was extremely helpful in ensuring that they were providing a rich hands-on learning experience all while teaching us how to operate the machines. We weren’t just told to do things a certain way, but why to do them that way, and how to create consistency in our future projects.”

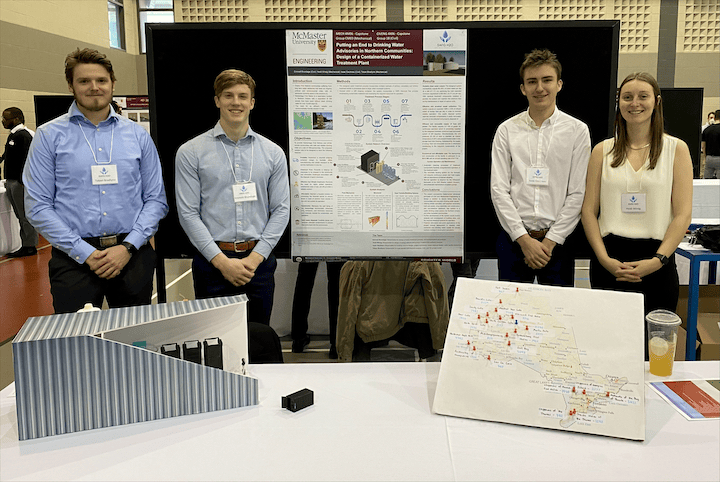

Safe Water Initiative Group (SWIG H20)

Product Name: Containerized Drinking Water Treatment Plant

Group members: Heidi Wirsig and Toban Bradlynn, Isaac Gautreau and Emmett Brundage

Access to clean drinking water in First Nations communities throughout Ontario has been an ongoing crisis with little to no progress and numerous failed attempts at creating solutions. Communities face excruciating economic and environmental factors making it extremely difficult to generate reliable sources of potable water. This project combines civil and mechanical engineering principles, combining knowledge on and infrastructure and manufacturing to design an effective, efficient, and affordable water treatment plant inside a recycled shipping container with an emphasis on sustainability and accessibility for remote communities.

This project brings focus to the ongoing suffering of residents in communities experiencing water quality advisories and initializes an alternative approach to creating feasible solutions. The group hopes that their method can be adopted and further developed to create a viable solution to relieve residents enduring long term water barriers and provide them with readily accessible drinking water.

The group credits their undergraduate experience for preparing them for the showcase, and life after Mac.

“Reflecting on our undergraduate years at McMaster, we are reminded of how well courses, programs, and extracurriculars are structured to prepare you for real world engineering applications and problem solving.” Brundage says. “Having the opportunity to participate in many group projects, clubs, teams, and events allowed us to learn from other’s experiences and help each other grow as individuals. We are thankful for our time at McMaster, the insight of professors, mentors, and instructors, and how well the engineering program has prepared us as we move into our future careers.”

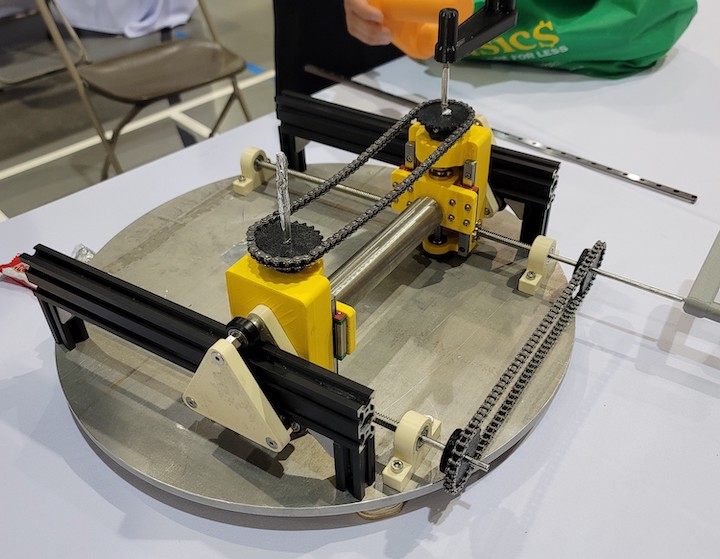

The Imagineers

Product name: Printing Press

Group members: Beshr Ibrik, Hosam Rezk, Mohammed Alshehri, Hazem Elkhaiat

The project aims to redesign the conventional etching/printing press to make it more accessible for people unable to stand for long periods of time (if at all) as well as people with motor difficulties in general. The project is a collaboration between the Department of Mechanical Engineering, School of The Arts (SoTA), as well as Centre [3] for Artistic + Social Practice.

The project is dedicated to people who are less fortunate which is why this project is very special,” says Alshehri. “Working on it throughout the year meant a lot more than just a capstone project for marks. I believe there is a lot of impact this can create beyond the time I spent working on it. The opportunities it opens to the people who need it will make a difference in their lives and provide more value. I hope many people find the new printing press design helpful and I hope it helps them get more opportunities in arts, that is sometimes restricted to a portion of the community due to the instruments not being fully accessible. On a larger scale, I hope the design principles used will be applied on many other projects to make many devices universally accessible so that less able-bodied individuals can have more independency.”

“Collaborating with my group on this project proved to be an enriching learning experience, from conception to completion,: shares Rezk. “We had the opportunity to go through each stage of product development and gain a deeper understanding of the decision-making process that goes into it. It was rewarding to work hard on a project that requires impactful solutions to help people in need. Our client, Centre[3], were very helpful in helping us understand the challenges they faced, and their feedback was invaluable during the design process. Additionally, working in the machine shop was an essential aspect of our engineering education and provided us with practical experience that we’ll carry forward throughout our careers.”

“Looking back on the past 5 years, I would say the application of the certain equations and putting everything together to see a result that used to make no sense to me, really come together in the end,” reflects Elkhaiat. “Whether that is through the co-op experience or the projects where we applied some of the design concepts and topics we learned. I would say the best part was getting to see my own design or idea implemented on a full scale and working on the job or having something interact with it. Really fulfilling and shows me why I chose engineering in the first place. To help people and solve problems to make things better.”

Photos by Sachi Chan. Explore more photos from the expo.

Check out our Capstone coverage on Instagram.

Congratulations to our winning Capstone project teams:

| Competition | Group | Student Team Lead | Project Name |

|---|---|---|---|

| Best Use of Mechanical Design Group | MECH6 | Cole Elford | SV01 – Hobby Tensile Tester |

| Best structural design Group | CIVIL2 | Lindsay Lee | The Whitefish Centre |

| Best Process Design Group | iBIO18 | Gurleen Dulai | Miniaturization of the Vmax Constant Pressure Test |

| Best use of Machine Learning Group | ECE41 | Tingyi Song | Mind Mobility |

| Best use of mathematical modelling in engineering design Group | iBIO13 | Anoop Dhillon | ePID (Equine Precision Inhalant Delivery) |

| Best use of Design Thinking Group | ECE23 | Stephen Danku | Lighthouse |

| Best use of Design Thinking Group Co-winner | iBIO6 | Diana Cancelliere | Spintroller: Automating Microcatheter Rotation For Coronary Chronic Total Occlusions |

| Best use of engineering design best practices Group | SW16 | Wei Xu Wang | Utrition |

| Best Printed Circuit Board design Group | ECE36 | Robert Oldfield | Hardware Password Manager (HPM Key) |

| Best safety analysis Group | CHEM6 | Elody Julien | Heavy Water Upgrading System Design Project |

| Best plan for manufacturability Group | iBIO22 | Victoria Ng | Dron-livery |

| Best biomedical innovation Group | iBIO6 | Diana Cancelliere | Spintroller: Automating Microcatheter Rotation For Coronary Chronic Total Occlusions |

| Best Impact on Sustainability Group | iBIO20 | Madison Lockwood | Medical Waste Reduction – Degradable Surgical Gown |

| Most environmentally conscious project Group | MECH41 | Heidi Wirsig | Water Treatment System |

| Most energy efficient design Group | CHEM5 | Anjuli Joachim | The Electrification of Commercial and Industrial Heating Systems |

| Best design for accessibility Group | iBIO4 | Saher Aslam | Low-cost Manganese Measurement System |

| Best design for accessibility Group Co-Winner | SW15 | Maxwell Turek | Smart Serve |

| Best design for accessibility Group Co-Winner | SW3 | Jordan Bierbrier | Synesthesia Wear |

| Best design for accessibility Group Co-Winner | iBIO19 | Prerana Keerthi | Biomusic: Physiological signals for emotion recognition |

| Best industrial application Group | CHEM1 | Aimen Aleem | Wastewater Treatment Plant Design via Simulation and Optimization |

| Best industrial application Group Co-Winner | SW5 | Steven Ramundi | The Nursery Project |

| Best industrial application Group Co-Winner | iBIO8 | Maya Czerwoniak | Blood Spatter Analysis Training Device |

| Most Likely to Win Dragon’s Den Group | iBIO14 | Juliana Onesi | Smart CPR Manikin: CPRobot |

| Best Marketing Material Group | iBIO23 | Lily Zhong | The Manipulet |

| Best Marketing Material Group Co-Winner | iBIO19 | Prerana Keerthi | Biomusic: Physiological signals for emotion recognition |

| Most Impressive Prototype Group | ECE36 | Robert Oldfield | Hardware Password Manager (HPM Key) |

| Most Impressive Prototype Group Co-Winner | ECE12 | A. Noori | HUDARA |

| Most Impressive Prototype Group Co-Winner | ECE41 | Tingyi Song | Mind Mobility |

| Most Impressive Prototype Group Co-Winner | iBIO22 | Victoria Ng | Dron-livery |

| Most Impressive Prototype Group Co-Winner | SW2 | Jessica Bae | EMAnator |

| Best App Group | SW23 | Veerash Palanichamy | UnderTree |

| Best App Group Co-Winner | CS18 | Benjamin Kostiuk | QueueTime |

| Most Rigourous Testing Group | iBIO20 | Madison Lockwood | Medical Waste Reduction – Degradable Surgical Gown |

| Best Booth | iBIO6 | Diana Cancelliere | Spintroller: Automating Microcatheter Rotation For Coronary Chronic Total Occlusions |

| Best Booth Co-Winner | MECH6 | Cole Elford | SV01 – Hobby Tensile Tester |

| Best Booth Co-Winner | MECH41 | Heidi Wirsig | Water Treatment System |

| Best Booth Co-Winner | ECE36 | Robert Oldfield | Hardware Password Manager (HPM Key) |

| Best Booth Co-Winner | iBIO15 | Muna Sabouny | IFlowPlate TEER |

| Best Video | iBIO13 | Anoop Dhillon | ePID (Equine Precision Inhalant Delivery) |

| Best Video Co-Winner | MATLS1 | Anne Calderon | Boriding of Multicomponent Stainless Steel Alloys |

| Best Video Co-Winner | SW13 | Aaron Li | Cyclops Ride Assist |

| Best Video Co-Winner | SW18 | Bowen Zhang | Digital Twin Forest |

| Best Video Co-Winner | SW24 | Qinglong Liu | Hairesthetics |

| Best Project | ECE36 | Robert Oldfield | Hardware Password Manager (HPM Key) |

| Best Project Co-Winner | MECH6 | Cole Elford | SV01 – Hobby Tensile Tester |

| Best Project Co-Winner | iBIO1 | Sainan Chelvarajah | Just Rehab – Wearable Rehabilitative Device |

| Best Project Co-Winner | iBIO19 | Prerana Keerthi | Biomusic: Physiological signals for emotion recognition |

| Best Project Co-Winner | iBIO22 | Victoria Ng | Dron-livery |