About Us

Solving Industry Manufacturing Challenges Through Applied Research and Testing

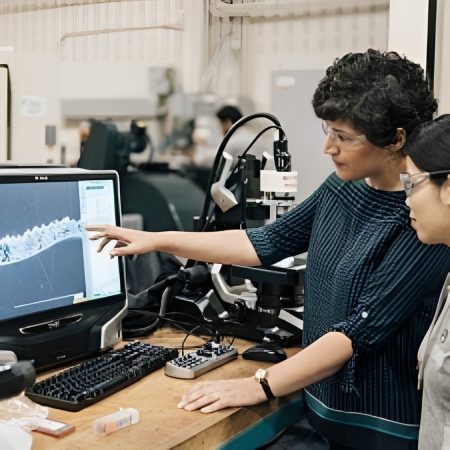

The McMaster Manufacturing Research Institute (MMRI) partners with industry to solve complex mechanical engineering and manufacturing challenges through applied research, advanced testing, and hands-on collaboration. With expertise spanning additive manufacturing, advanced manufacturing processes, and materials testing, the MMRI brings together professional engineers, machinists, researchers, and students to deliver practical, scalable solutions.

Our strength lies in our diversity of machines, methods, and expertise. MMRI is structured to address a broad spectrum of manufacturing and mechanical engineering challenges, adapting our expertise to the needs of each partner. From rapid prototyping to process optimization and long term technology development, MMRI combines research, testing, and consultation to create lasting solutions. Explore our success stories to see how we turn industry problems into real world results.

Graduate and undergraduate students work directly on real industry problems, gaining experience across sectors including aerospace, automotive, healthcare, and beyond. Check out our ‘Study with us‘ page to learn more about student opportunities.

Our Facilities

In 2023, the MMRI opened a new facility at McMaster Innovation Park, located at 230 Longwood Road South, our new location allowed us to expand our capacity to support advanced manufacturing research, testing, and industry collaboration. If you are looking for a place to machine, R&D, test, or develop in Ontario, look no further then the MMRI.

-

-

Take a virtual tour of the MMRI

-

Highlighting Our Impact

Check out our socials to learn more about our current projects.

Technology transfer opportunities

From Research to Implementation

MMRI emphasizes technology transfer and long term industry impact by translating research outcomes into implementable solutions. Through close collaboration with industry partners, the MMRI supports knowledge transfer, process implementation, and sustained performance improvement beyond the life of individual projects.

We offer technology transfer opportunities for:

- Tooling selection

- Tool path development

- Process monitoring

- Process parameters

We combine our experience with state-of-the-art equipment to meet the sophisticated research and development needs of leading manufacturers.

The focus of this research group has been to develop intelligent solutions to issues faced by manufacturers in all steps of the machining process.

The MMRI can help you choose the correct tool for your process.

We use your material, process and tooling information to identify tool geometries, edge prepping and advanced tool coating which will significantly extend tool life and performance.

Our evaluation not only helps save tooling costs, it increases tool productivity and part quality. You will no longer have to “babysit” your processes thanks to the reduction of scrap rates.

Improve your cycle times and push your machines to their full capability by utilizing the process simulation and optimization software: MACHpro.

MACHpro is the most advanced software of its kind in the market. With the ability to simulate your process in 5-axis and to automatically update your NC program, this software will help you to fully maximize your machines and tooling.

We can tune your process parameters, such as feeds and speeds, to optimize your production.

We use CUTPRO, a software developed by Manufacturing Automation Laboratories at the University of British Columbia, to intelligently identify optimal feeds. Our processing can improve your tool life, productivity, surface finishing and greatly impact your efficiency.

With use of our software, MMRI-Monitoring, you are able to track process production and production issues.

Our software is able to back your enhancement decision with detailed process data. It will alert you of production issues in real time, reduce variance and hold tighter tolerance on key dimensions.

We have extensive experience in machining process optimization and improvement.

With our help we can improve part quality and productivity while lowering your costs. We have partnered with the Manufacturing Automation Laboratories at the University of British Columbia to be able to offer expertise and solutions to a wide range of machining challenges.