The first cohort of students to complete the new Integrated Cornerstone Design Projects in Engineering course, which brings together competencies in coding, graphic design, materials and engineering practice, demonstrated their design prowess in the year-end project showcase on April 14th.

Not only were the students who joined McMaster Engineering in September the first to complete their initial year completely online, they were the first to take a newly launched, project-based engineering course.

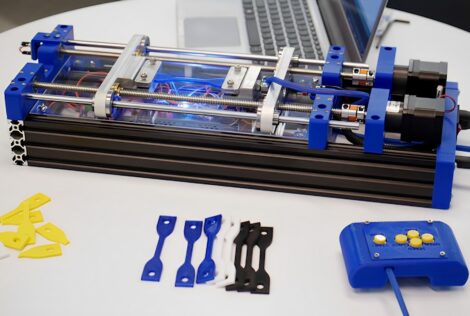

The Integrated Cornerstone Design Projects in Engineering (1P13) is a two-semester course combining learning from four different engineering competencies – programming, graphic design, materials and engineering practice. In all, 1,027 first-year students were divided into three sections and design teams of four, with each team having the freedom to create their unique designs.

A challenge was issued to students to design solutions for a real client; a visual artist based in Toronto who experiences a combination of physical ailments that impede her work. In their assigned groups, students designed assistive devices to allow her to work longer while experiencing less pain and discomfort.

With guidance from the 1P13 faculty and teaching assistant team, every team produced successful results from their research and design work, applying the skills they learned throughout the year in their final projects. Here are the winners, along with special mentions, from each section.

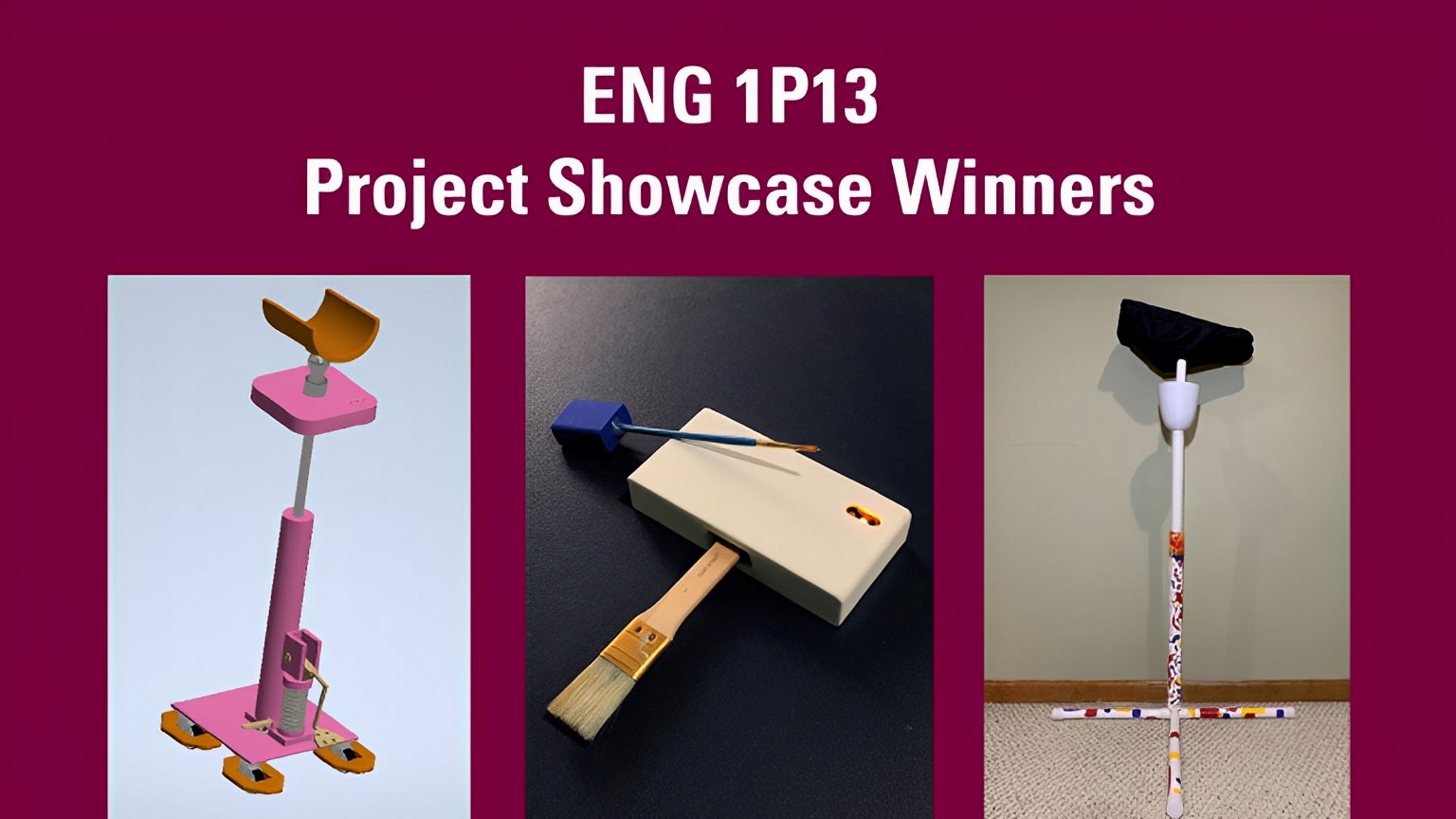

In each section, over 80 designs were narrowed down to just five finalists to be showcased on Wednesday, April 14, the last day of classes. A panel of judges, including the client, selected three winning design projects – one from each of the three sections.

Section 1 Winner: “Painter’s Grip Pro”

Team Thursday-07

Group Members: Blake Freer, Dehe Ming, Sam Parent and Kartik Chaudhari

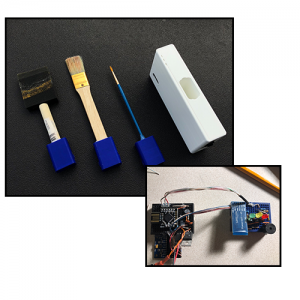

The Painter’s Grip Pro is an assistive device designed to help the client more easily grip her paintbrushes and indicate when she begins showing signs of a flareup of her fibromyalgia. Different paintbrushes can be easily swapped in and out of the handle, making it compatible with a wide variety of brush sizes. Accelerometers within the handle can detect hand tremors that indicate that the client should allow herself some rest to avoid a flareup, which can often prevent her from being able to paint for up to a day.

In initial meetings with the client, the team realized that one of her struggles is the unpredictability that comes with her physical challenges. They aimed to create something that increases her comfort and reduces the unpredictability, allowing her to enjoy her work more.

“Everyone on the team brought different skills and talents to the project. Working together, we created a prototype that we’re proud of and it seems the client and judges liked it, too,” said Kartik Chaudhari.

The students in this group are planning to specialize in mechatronics, electrical and software engineering as they proceed into second year, and their design certainly demonstrates a passion for these fields.

Section 2 Winner: “The Flamingo”

Team Thursday-53

Group Members: Andrea Berceanu, Michael Wolfe, Moly Mikhail and Grace Xing

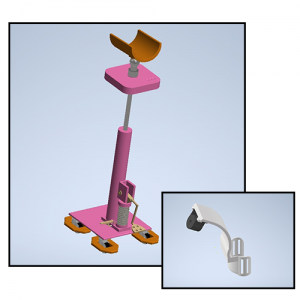

“The Flamingo” is a specially designed arm support. It is intended to relieve stress on the client’s shoulder and arm while she is painting – particularly when painting fine details. While other groups pursued a variety of designs for arm support devices, what set this design apart was the integration of a foot pedal to raise and lower the padded arm support. This makes it easy for the client to operate when she may have paint on her hands, or her hands are beginning to feel fatigued. Their design also included a custom paintbrush grip, to help reduce fatigue while painting.

The group explored quite a few mechanisms for adjusting the height before arriving at the foot operated pneumatic pump system that set their design apart from the competition.

“This project was a culmination everything we learned in the course. And even though we didn’t get the first year we expected when we applied, the program handled the shift to online learning very well and gave us the support to succeed, despite the challenges,” said Grace Xing.

Asked which engineering disciplines the team members are interested in pursuing, they shared a diverse list, including chem & bio, electrical, engineering physics and software. No doubt they will continue to produce excellent work throughout their student careers and into their professional careers to follow.

Section 3 Winner: “The Lean-on-me”

Team Friday-17

Group Members: Renee Twyford, Christian Petricca, Rafik Manla Hassan and Hala Labidi

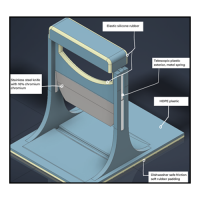

“The Lean-on-me” is an arm support mechanism that with a focus on comfort. In function the Lean-on-me is similar to The Flamingo above, though the design focus differs between them. While The Flamingo’s key feature is its easy to use foot pedal for height adjustment, it’s clear that the elbow rest component was the focus of this group’s design. The team selected materials that would be both durable, easy to clean and provide a soft cushion for the client’s arm. Another notable component of the design is the ball-and-socket joint that supports the elbow rest. This allows the client more flexibility of motion while painting, without sacrificing support. Below the socket joint, the prototype construction uses PVC tubing that is strong, light, and inexpensive. Hight adjustment is accomplished with a simple support pin.

The group began their design process with eight different concepts, eventually narrowing it down to the arm support. They incorporated simple and effective solutions to achieving their design objectives and share an appealing prototype with the client.

“Mac did a good job of debuting the online experience. The faculty, instructors and teaching assistants for the course were very receptive to students and our feedback. They adjusted aspects of the course to fit the online experience,” says Christian Petricca.

Rafik, Hala, Christian and Renee are interested in pursuing software, electrical and computer and chem & bio engineering.

Special Mentions

From Section 1: “The Precise Slice”

“The Precise Slice” is a design to help the client with meal preparation. A vegetable chopping system designed to minimize force to slice vegetables as large as a typical squash, while being easy to clean and maintain.

From Section 2: “Hyper Glove”

The Hyper Glove is an assistive glove system that augments the client’s grip when holding paintbrushes. It uses a series of elastic cords that can be tightened to reduce the grip pressure required to hold a brush for prolonged periods of time. Designed to be breathable and comfortable, as well as easy to clean, the Hyper Glove offered a distinct solution for the client’s needs.

From Section 3: “The Supporter”

The Supporter is another armrest device built atop a wooden tripod design. What is notable about this design is how at-home it would look in an art studio. With further refinement of the adjustment mechanisms and added stability, The Supporter could be an excellent design for the client’s needs.