Engage with our institute

The McMaster Manufacturing Research Institute (MMRI) has an enduring commitment to foster innovation and collaboration.

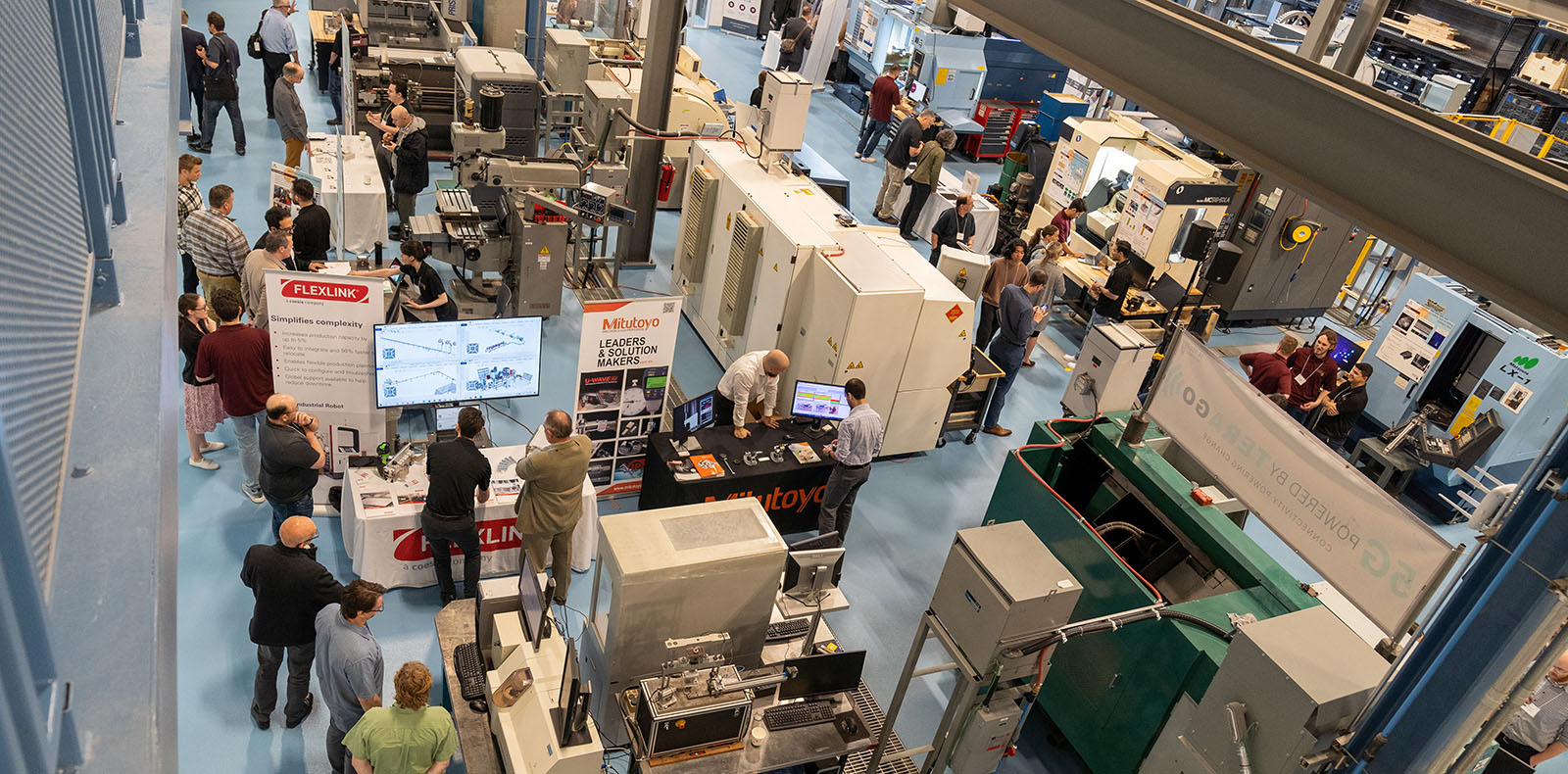

Our events bring together leading experts to create a space of dynamic exchanges and shared knowledge.

Opportunities include our annual open house, speaker series and webinar series

Ninth annual forum highlights; MMRI’s commitment to manufacturing innovation

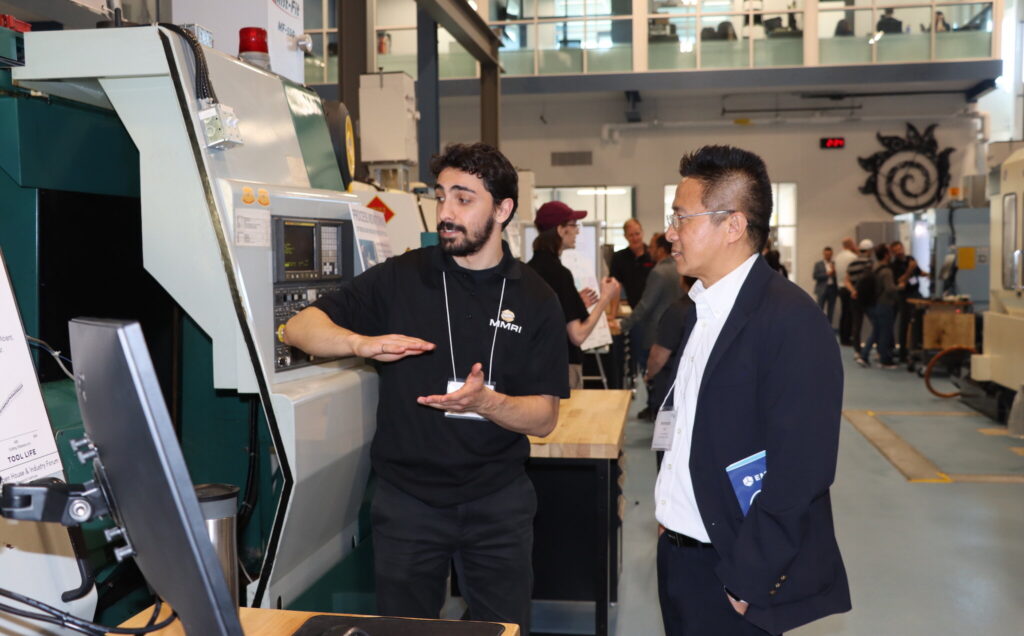

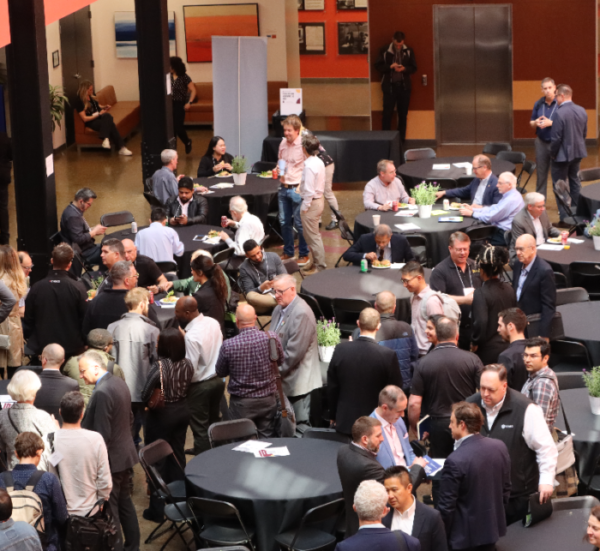

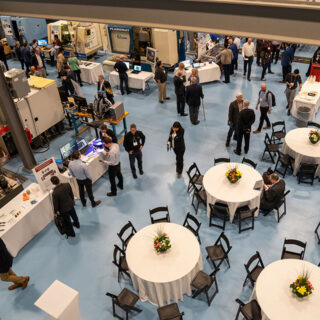

The McMaster Manufacturing Research Institute (MMRI) hosted our annual Open House and Manufacturing Forum on May 2. The day began at the McMaster Innovation Park (MIP) Atrium for the Manufacturing Forum, later transitioning to the MMRI for graduate student-led presentations and networking. With more than 200 industry professionals, students and government representatives in attendance, the event provided a dynamic platform for networking, learning and engaging in interactive demos.

“There is an urgent need in the US and in Canada to focus on the adoption of Smart Manufacturing and the opportunities that we have collectively to become more competitive manufacturing nations.”

Manufacturing Forum;

Two insightful panel discussions that featured esteemed speakers from diverse sectors.

Panel 1: Identifying Opportunities

Brendan Sweeney, Managing Director Trillium Network for Advanced Manufacturing (Moderator)

Panelists:

- Bill Walker, President & CEO Organization of Canadian Nuclear Industries (OCNI)

- Verlyn Smith, Downsview Aerospace Innovation & Research (DAIR), Supplier Development Initiative Manager

- Mark Brown, COO at Pasqua First Nations (PFN) Group of Companies/ President at Pro Metal Industries Ltd.

- Jennifer Bauman, Associate Professor, Electrical and Computer Engineering

Panel 2: Realizing Opportunities

Jean-Pierre Giroux, President, Excellence in Manufacturing (EMC) (Moderator)

Panelists:

- Philippe Dupuis, Smart Manufacturing Architect, REMAP Network

- Stephanie Holko, Director, Project Development NGen

- Daniel Vucinic, Chief Executive Officer, TERAGO Network

- Jeff van Heumen, Assistant Vice-President, Business Development, Ontario Centre of Innovation (OCI)

The MMRI staff expresses gratitude to everyone who attended the forum and open house events and to the esteemed speakers and exhibitors. As a thank you to this year’s speakers, the MMRI made a donation to McMaster’s Community Outreach-led Venture Camps, which aim to inspire the next generation of STEM innovators.

Explore the 9th annual forum

Watch this YouTube video to learn about the annual open house and industry forum.

Highlights from the 8th Annual Manufacturing Forum (2023)

The McMaster Manufacturing Research Institute welcomed over 350 industry experts, researchers, students, and vendors to our eighth annual Open House and Industry Forum, which took place on Thursday, May 11, 2023. The event was a resounding success, thanks to our keynote speaker, panelists, sponsors, staff, students, and attendees.

The event’s keynote speaker, Tony Schmitz, is a leading expert in manufacturing who addressed the topic of manufacturing in a digital world during his keynote presentation. During his keynote speech, he shared valuable insights on the various tools available to access and measure vibrations within specific machines and how digital tools can be used to find ideal machining parameters. Schmitz is renowned for his research in the field of manufacturing, particularly in areas such as machining dynamics, machine learning, and additive manufacturing. He is dedicated to supporting the US machine tool industry, and his work continues to optimize manufacturing processes.

The day continued with the panel section of the forum, focusing on topics including:

- the 5G mmWave private network, discussed by panelist David Wale, Director at Terago

- machining, automation, and AI, discussed by panelist Alexander Berger, President and CEO of A. Berger Precision Ltd

- robotics, discussed by panelist Kevork Sevadjian, CEO and Co-Founder at Gastronomous

- AI, discussed by panelist Maryam Emami, CEO at AI Materia Inc

- training and upskilling, discussed by panelist Medora Uppal, CEO at the YWCA Hamilton.

To thank our panelists, the MMRI made a donation in each of the event speakers’ names to McMaster Venture Camp.

Highlights from the 7th Annual Manufacturing Forum (2019)

What happens when you bring a group of industry leaders passionate about manufacturing into one room? For some, it becomes one of the highlights of the year.

The seventh annual forum and open house on Thursday, May 2, 2019 was a success with over 250 industry representatives, researchers and students in attendance.

The keynote speakers Cameron Schuler, Irene Sterian, and Jayson Myers delivered engaging and impactful presentations centred around Artificial Intelligence and Machine Learning in Manufacturing.

John Preston, Associate Dean, Research and External Relations for McMaster Engineering, reflected on this year’s open house saying:

The MMRI Open House is one of the highlights of the year. It brings hundreds of people from industry to McMaster and is a great chance for us to introduce ourselves, what we can do and what problems industries are facing and celebrate past successes.

Other speakers included:

- Pieter Jan Provoost, Business Group Leader Markets / Director Energy Technology Club / International Relations, Agoria

- Gina Succi, Chief Executive Officer at Westhill Innovation Inc

- Evert Nieboer, General Manager, Process Automation at ArcelorMittal Dofasco

- Shalabh Bakshi, Vice President, Digital Enterprise Services ASEAN, Siemens

- Simon Drexler, General Manager, Automation Products at ATS Corporation

With over 300 industry representatives, researchers and students in attendance, keynote speakers, Jayson Myers, CEO of Next Generation Manufacturing Canada, and Don McIntosh, Senior Fellow of Manufacturing Technology, Pratt and Whitney, shared their insights on the future of manufacturing in Canada.

“The Supercluster doesn’t begin and end in a local area,” Myers said. “What we’re really trying to do is leverage as much of the research and development; the knowledge and the technology assets that we have in this region for the benefit of manufacturers and the benefit of the Canadian economy as a whole.”

Keynote speaker:

Michael F. Zaeh, Prof. Dr.-Ing, TU Munich, Germany: Industry 4.0 Made Tangible -Tangible Things Within Industry 4.0

Expert Panel moderated by Dennis Darby, President & CEO of Canadian Manufacturers & Exporters

- Roger Hallett, Festo: Industry 4.0 – The Future of Manufacturing Begins Today

- Daniel Madrea, DMG Mori: Industry 4.0 – Path of Digitalization

- Joris Myny, Siemens: Driving the Digital Enterprise

- Rick Huibregts, Cisco: Re-defining Manufacturing in the Age of Digital Disruption

The MMRI has hosted webinars, such as:

The A to Z of materials testing in the composites industry

A four-part series sponsored by ZwickRoell and the MMRI, which covered:

- Further mechanical test methods often performed for composites, including interlaminar fracture toughness, compression-after-impact (CAI), open- and filled-hole tension and compression and bolt-bearing

- Testing at different time durations, from creep to high strain rate, and different methods for compression testing of composites, including applicable test standards, test fixtures, test validation criteria and failure modes

- The importance of accurate strain measurement and the different requirements for strain measurement dictated by the basic in-plane composite test methods (tension, compression and shear)

Presenters: Dr. Hannes Körber, ZwickRoell Industry Manager for Composites and Dr. Mehdi Dargahi, Regional Sales Manager

The MMRI has hosted in-person seminars, such as:

A practical workshop on cutting tools for high performance machining operations

This workshop helped participants learn how to choose the right tool and maximize its use. Instruction covered:

- Choosing the best geometry to prevent tool damage, achieve the highest surface quality, perform at the highest productivity, better manage chips/swarf

- Reduce tool wear by understanding wear mechanisms, learning how to measure tool wear, finding the root causes, learning preventative actions.

- Learning about different classes of tool materials/coatings, such as performance, properties, limitations and characterization.

Organizer and instructor: Maryam Aramesh.

Guest lecturer: Jose Mario Paiva.