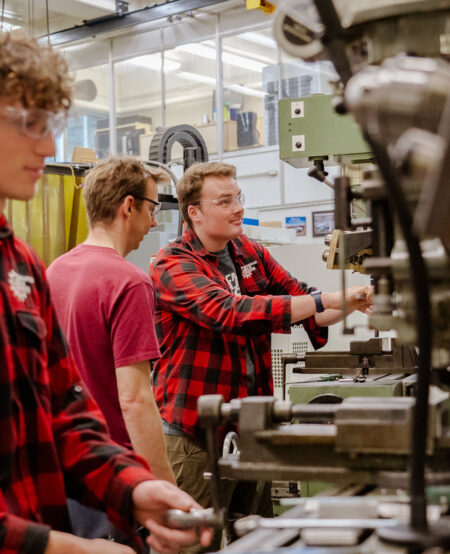

Main shop

The main machine shop provides design consultation, precision machining, welding, fitting and assembly (mainly on prototypes), custom-designed parts and repair or modification of existing equipment.

We work with a broad range of metals such as aluminum, stainless steel, as well as various other materials such as Teflon, Delrin, graphite, acrylic and polycarbonate. Our strength is our many years of experience in a jobbing shop environment both here at the university and also out in industry that enables us to provide quality machining.

Work within the shop is done on a cost-recovery basis of time plus materials with our main customers being the Faculty of Engineering, Faculty of Science and the McMaster Nuclear Reactor.