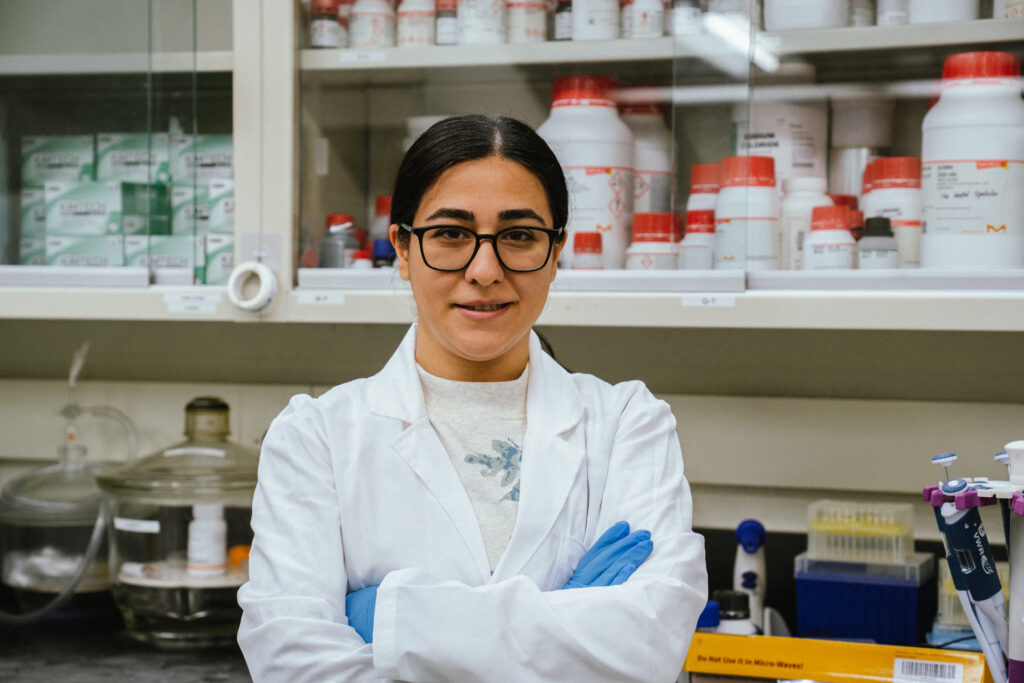

For Zahra Teimouri, the opportunity to work with Drew Higgins and access the world-class facilities at McMaster’s Canadian Centre for Electron Microscopy (CCEM) was one she couldn’t refuse.

“My background is on catalysts for renewable energy applications and processes,” says Teimouri. “Dr Drew Higgins was doing the same thing but with renewable electricity. I knew I could do great work with him at CCEM.”

Fighting climate change at CCEM

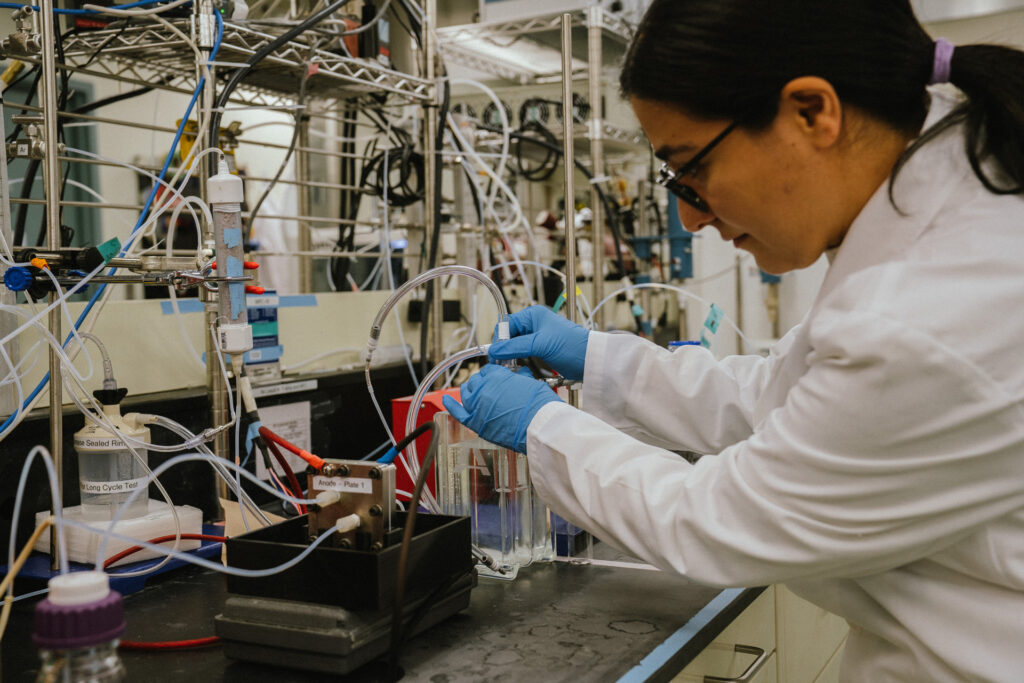

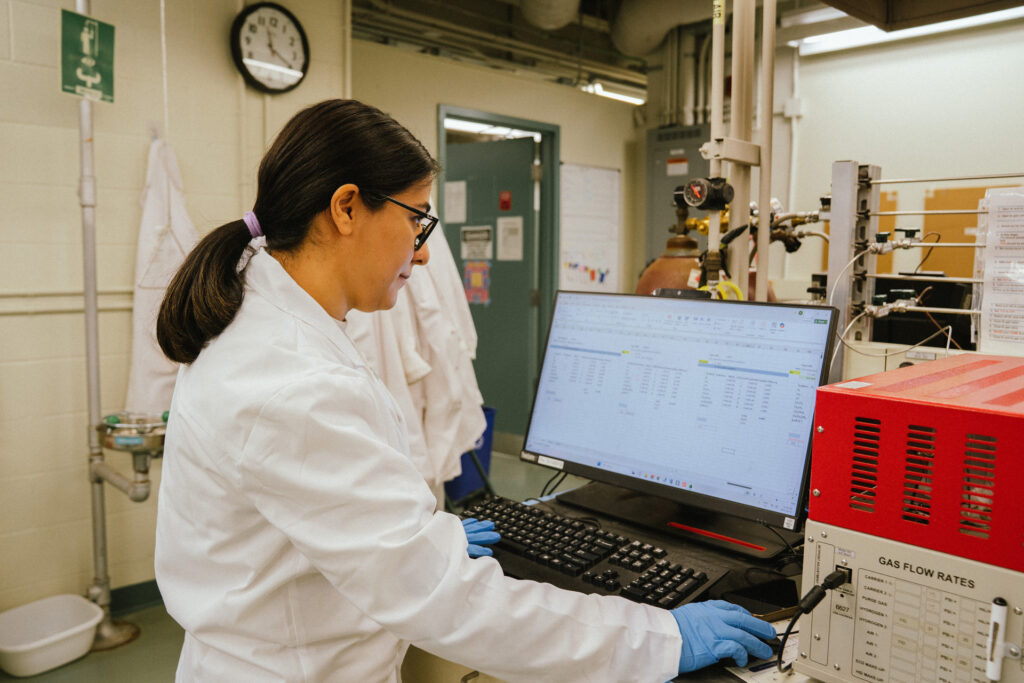

At CCEM, Teimouri is working on CO2 conversion into ethylene – a building block for plastics – using renewable electricity instead of fossil fuels.

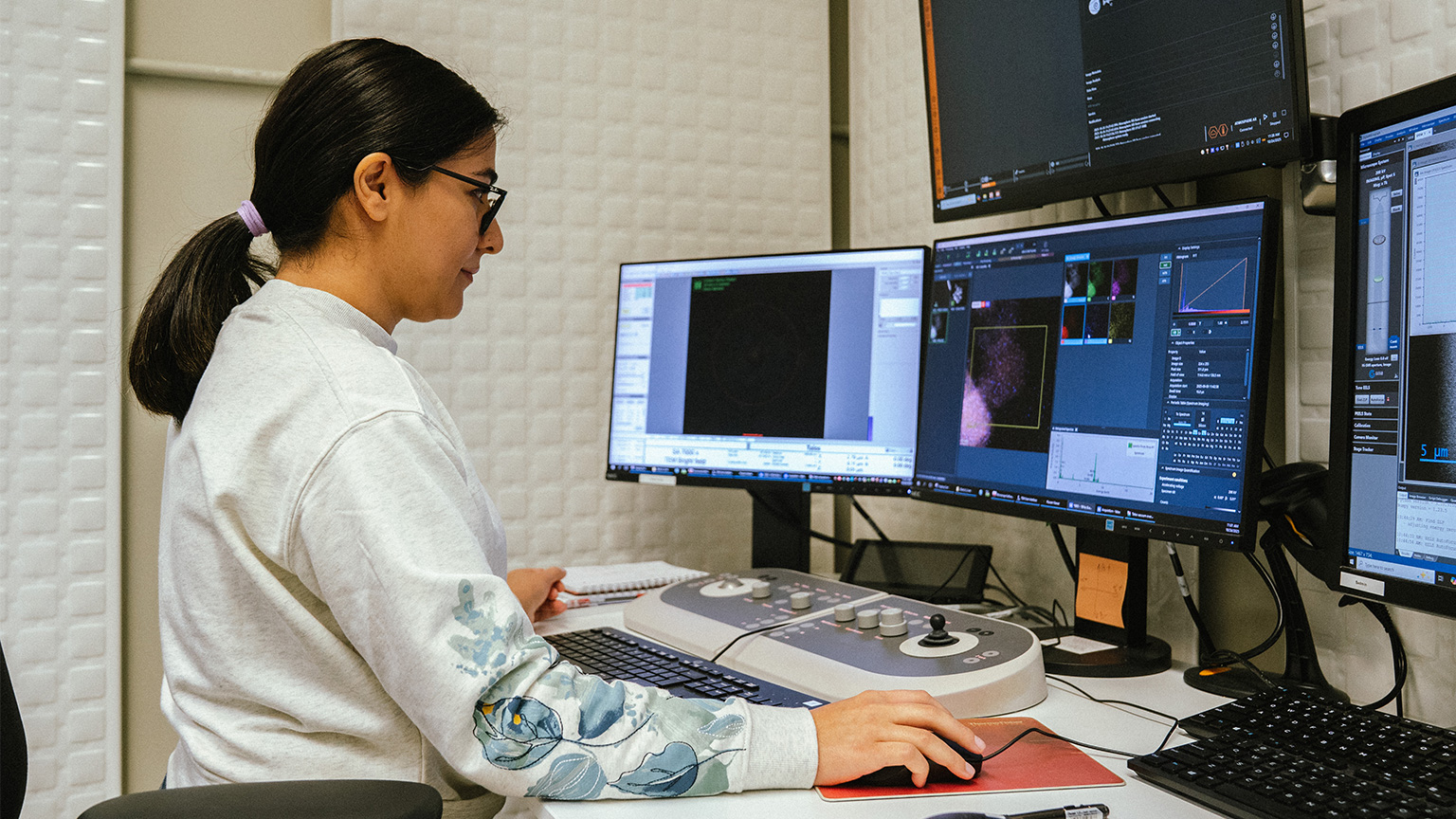

“To make better catalysts, I use in-situ transmission electron microscopy (in-situ TEM), which is essentially a high-speed camera that watches the catalyst at work under real reaction conditions,” says Teimouri. “Seeing how the catalyst changes in real time lets us redesign it so it stays active and efficient for longer operating periods.”

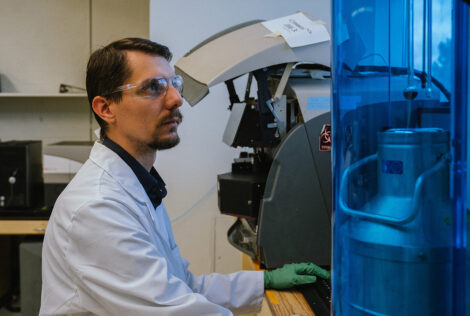

Teimouri is a super-user of the Thermo Scientific Talos 200X, equipped with in-situ liquid and gas cell experiments. Because of the unique facilities available at CCEM, Teimouri can advance her research in catalyst stability.

“The microscopes give us an opportunity to see what’s really happening inside the cells we’re studying,” says Teimouri. “And with the great staff at CCEM and the training they provide, we can use these machines independently for our research.”

Cheaper and cleaner energy

Teimouri says her goal is to design novel high-performance and scalable catalyst materials that converts CO2 plus renewable electricity into ethylene in a clean, reliable way.

“The biggest challenge is catalyst stability,” she says. “My research focuses on understanding and solving that problem using advanced imaging and materials design.”

Teimouri is driven by sustainability, and the long-term impact of her research benefits both industry partners and the community.

“Finding renewable sources of energy is critical in our world right now,” says Teimouri. “We’re creating a high-value product for the industry and lowering CO2 emissions at the same time, so it’s a win-win.”

“We are reducing dependability of the industrial sectors on carbon fuels. For example, ethylene is getting produced by fossil fuel-based processes, which are energy-intensive and emit high levels of CO2. In CO2 electroreduction, we are conducting this with renewable electricity, which is both cheaper and cleaner.”

Collaboration through mentorship

For Teimouri, the mentorship aspect of her post-doctoral fellowship experience is one of the most rewarding.

“Mentoring is a huge part of my work,” she says. “Having the opportunity to mentor graduate students from the beginning of their journeys is special. This includes giving them ideas, training them on instruments, and later on, helping them to write their manuscripts and scientific reports.”

Community partnerships

For Teimouri, the close relationships with industry partners sets McMaster apart. “We are finding solutions to real-world problems, and we are able to translate our ideas to our partners. They can then incorporate our ideas to their products to make a lasting impact on our communities.”