Challenging. Rewarding. Integration. Fun. Learning. Ambiguity. Gnarly. Tremendous. Memorable. These are the words students used to sum up their capstone experience. After a year of hard work, around 200 student projects were showcased in-person for the first time in two years at the Capstone Expo.

April 12 was a busy day for our graduating students as they showed off their capstone projects in both a virtual and in-person expo. Around 3,000 conversations happened during the virtual fair, with 500 alumni, industry partners, and McMaster community members signing in. Over 200 participants trekked to CIBC Hall and Burridge Gym to experience the projects in real life.

A few groups shared their experiences and lessons learned with us.

1. Cycle Safe

Software/Mechatronics

Team Members: Uzair Abbasi, Alex Rowinski, Kristupas Zermomskis, Scott Williams

“It’s a modular bike safety system intended to reduce injuries and bike-related fatalities. The way we do that is we bring automotive safety features onto the bike. On our bike, we have blind spot detection, we have a break light, as well as turning indication and the front headlamp. All of this can be controlled through a phone app that we have, the phone app isn’t required but it’s kind of just a quality-of-life thing.”

“The big thing for us was the modularity. We wanted to be able to have it so you can just mount it onto any bike, doesn’t require you to buy a specific bike. So we tried to do it with a more traditional road bike with bullhorn handles. All the components fit on that type of bike as well, which is what we were trying to go for.”

“Throughout the whole process of building it, I wanted to make it a finished project. But we kept getting told, it’s a prototype, it’s a prototype, it’s a prototype. So now that we’re here on the expo day, and we’re demo-ing our product, and it’s obviously not 100 per cent perfect right? But it’s functional as a prototype and people like it. People are positive towards it so for me it’s very rewarding.”

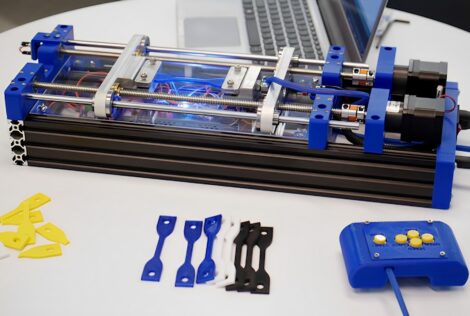

2. Open-source Accessible Game Controller

Electrical and Computer

Team members: Riley Mione, Taha Saqib, Kyle Thatcher, Thomas Lee

“Our project is an accessible controller hub. The idea behind it is that if you’re someone who has mobility impairments who can’t use a conventional standard controller, then this device would be for you. How it works is you can choose any peripherals you want, and plug them into the device just by aux cord. And you can make your own custom set up that works for you.”

“An inspiration for this project was having a friend who used a conventional controller in a different way which worked for them. Seeing as there were not many alternatives to conventional controllers in the past, we wanted to increase the availability of such options and make gaming more accessible to everybody. We also made sure that all of our software and our hardware is open source. We designed this board here, except for the micro-controller, and you can get all of this on GitHub. So you can make one for yourself if you’d like to.”

“One of the things that we wanted to do was that this would be your one stop for gaming hub for everything. The idea was to support PC gaming, Switch, XBox, Playstation. Problem with this is we made some design decisions early on that made it not impossible, but very difficult to do that. So project planning and doing research into your objectives to see if this is feasible with your plan is definitely really important.”

3. Spinosense – Smart-Sensing Spinal Board

Software/Mechatronics

Team Members: Zachary DeMelo, Emilie Lam, Lubna Najm, Sadiyah Razick

“We knew a lifeguard who was always complaining about different aspects of the spinal board. So that’s what kind of peaked the investigation into what are some of the drawbacks. And we just went with an open mind, “what is wrong with spinal boards.” And the big one that came up was the pressure source and we thought, that’s a really direct problem that we can target and focus on and we think we can find a solution for. So that’s what drove us there as our starting point.”

“I found a really valuable aspect about this project is that throughout our time in undergrad, we hadn’t really had an opportunity to carry out from start to finish a physical prototype in this way. We intended to do so, prior to this, but then obviously with COVID we had to stop those operations. So it was a really valuable experience to equip us to go into the workforce.”

4. Electric-Motorized Snowboard

Mechanical

Members: Justin Isenberg-Verrall, Alexander Du Bois, Patty Boucher, Caleb Young

“We basically made an electric snowboard. The idea of this is if you want to snowboard, but you’re not close to a ski hill, you can just take this to a park or to a trail and use it.”

“We just thought it’d be really fun and also it’s really nice that it combines mechanical ideas but also some electrical and a bit of code. It was a really good learning experience and also a really cool thing to have at the end of the day.”

“Manufacturing takes way longer than you think it will. The last 20 per cent of anything takes 80 per cent of the time. Our time for testing was a lot shorter than we hoped it’d be. So I think next time, just planning for how we’re going to manufacture and design things for ease of manufacturing.”

“Once we put it all together, we went ‘ok, it looks cool’…and then we tried it and it putted along, nothing really happened. We had to adjust the tension in the track, adjust the tension in the chain and then we increased the settings and it started to work and it was quite exciting.”

5. Plant Buddy – Automated Plant Care System

Software/Mechatronics

Team Members: David Carrie, Gengyun Wang, Zeyad Abd El Salam, Thaneegan Chandrasekara, Wenzhi Wang, Zirui Fu

“We are the Plant Buddy team, and our project is an automated plant care system. The system is designed to analyze plant growth conditions and provide optimal water and light levels for healthy and effective plant growth. The primary motivations behind the project were environmental and supply chain concerns in providing food for urban and city environments. In brief we sought to reduce the massive emissions and environmental damage that comes from transportation and large scale industrial agriculture, while also reducing dependency in urban/city environments on outside food.”

“The complexity of tackling this issue was much deeper than we initially thought, in particular the practical components of cost and user adoption. Small scale production without supplier relations proved costly compared to rival production costs. On the user side there was a wide variety of interest, however different needs and levels of horticultural proficiency affected customers’ product expectations. Compromises and adaptations were made to cater to the users, granting more control or greater simplicity based on user requests.”

“The most memorable moment was when we got together to complete the final prototype. After many months of work and planning we assembled the project. We wanted to see how it would behave so we turned off the lights and powered it on. The room went dark, and the system powered on and came alive. It was as if out of a product promotional video. At that point we felt and saw the results of our work, and the feeling was incredible.”

Drum roll please…

A group of judges who viewed the projects during the Expo, came to the conclusion that these projects were top notch:

1. Best use of new materials – Alexander Park Redevelopment

2. Best biomedical innovation – Biofeedback Glove

3. Best use of mechanical design – Trueinator (with honourable mention to Nanostructure Fabrication on Bio Polymer)

4. Best structural design – Vaughan Midrise Project (with honourable mentions to London International Airport Expansion and New McMaster Transit Hub)

5. Best plan for manufacturability – Spinal Test Apparatus (with honourable mention to Modular Farming Units and Distribution Centre)

6. Most likely to win Dragon’s Den – SafeEats

7. Best marketing material – Spothole

8. Best industrial application – Single Use Technology (SUT) Systems Database for Sanofi Pasteur’s B100 Manufacturing Facility (with honourable mention to Gamma Guardian)

9. Best tasting project – Spothole

10. Best process design – QuiKDetect (with honourable mention to Urban Vertical Farming)

11. Best app – P.O.S.E.

12. Best use of machine learning – On-Cue

13. Best PCB design – Terrasense

14. Best safety analysis – Headsup (with honourable mention SafeEats)

15. Best use of mathematical modelling in engineering design – Beta Buddy (with honourable mentions to DDR5 and MEDoNA)

16. Best use of engineering design best practices – NextStep: A Guidance Assist for the Visually Impaired (with honourable mention to V2Victory Project)

17. Best use of Design Thinking – Roomr (with honourable mention to Forensic Blood Spatter Test Device)

18. Most impressive prototype – NextStep: A Guidance Assist for the Visually Impaired (with honourable mentions to Design of a functional demonstration device for recruitment and Snowbot)

19. Most rigorous testing – Improving Material Selection and Heat Treatment for Intergranular Corrosion Resistance (with honourable mentions to Book Bazar and StayNTune)

20. Most creative use of additive manufacturing – GRASP bionic

21. Best impact on sustainability – BOOST – Dynamic Wireless Electric Vehicle Charging (with honourable mentions to Replacing Aerospace Grade Aluminum with Carbon Fiber Reinforced Polymers and Modular Earth School Design in Ghana)

22. Most environmentally conscious project – Modular Earth School Design in Ghana

23. Most energy efficient design – V2Victory

24. Best design for accessibility – SafeEats