While top Google results for microneedle patches point to acne treatments and anti-aging solutions, researchers at McMaster University are proving that these tiny tools can be more than skin-deep. They see an opportunity to transform food safety and sustainability.

Microneedle patches, says Akansha Prasad, can be adhered to food packaging like raw meat or ready-to-eat meals and indicate when bacteria are present and deliver bacteriophages – or phages for short – to kill it. “In a country that wastes nearly half of the food it produces and in a time of growing food insecurity, it’s critical we innovate in this industry,” she says.

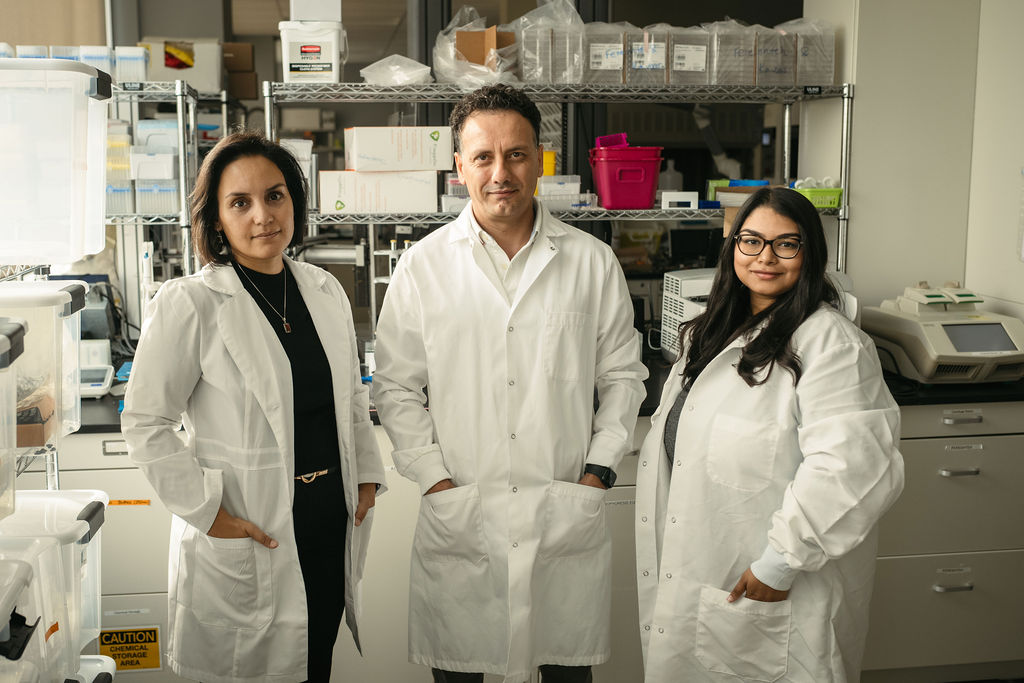

The PhD candidate in biomedical engineering is working with professors Tohid Didar, Zeinab Hosseinidoust and Carlos Filipe to not only develop the technology but to leverage their entrepreneurship experience to address commercial requirements in an industry with strict standards. This work was also co-authored by Shadman Khan, a recent PhD graduate from the Didar Lab. Two papers – one in Advanced Science and one in Science Advances – published this month by the McMaster team are advancing understanding of this novel application, putting particular attention on disrupting consumer-level waste.

In a country that wastes nearly half of the food it produces and in a time of growing food insecurity, it’s critical we innovate in this industry.

Sensing spoilage with a secret ingredient

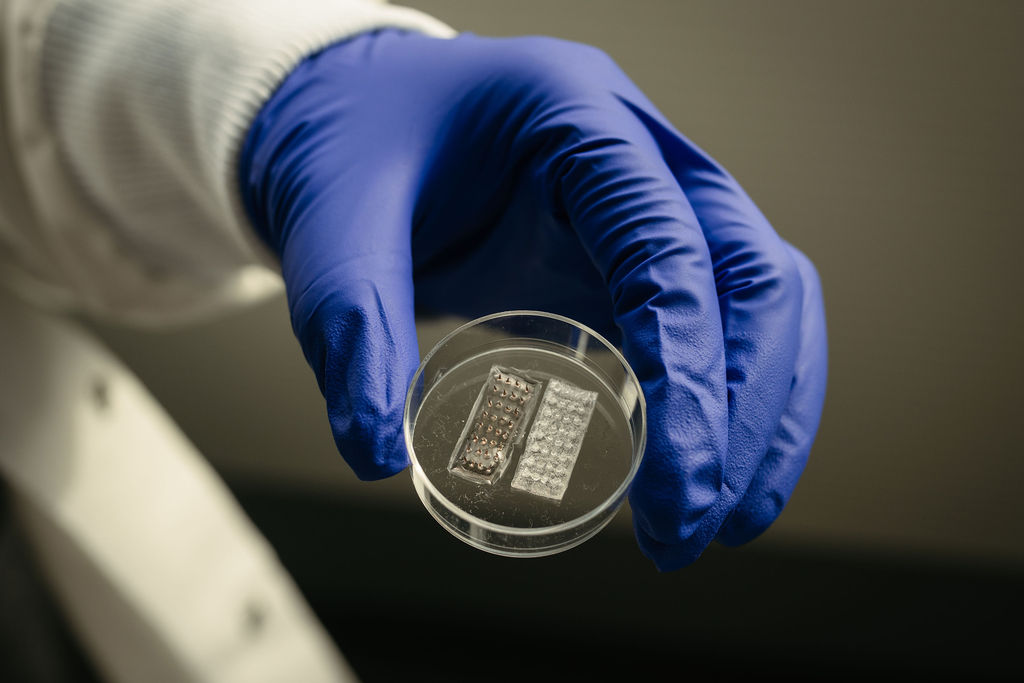

Creating a gel-casted microneedle patch in their lab, the McMaster team found a non-destructive method to assess freshness, especially in sealed products like packaged meat.

The microneedles are rigid and shelf-stable in their dry form, similar in strength to frozen needles. This allows them to pierce food packaging without causing damage. Once inside, they rehydrate upon contact with the moisture-rich tissue of the food, transforming into a soft hydrogel that begins to monitor spoilage.

Turning to a secret ingredient – red cabbage anthocyanin, a natural pH indicator – embedded within the gelatin matrix, the McMaster team discovered that as food degrades, microbial growth and toxin accumulation cause pH levels to shift. As pH shifts, the patch turns from purple to blue, indicating spoilage.

“pH metres are commonly used in industry to assess food quality, but they’re too complex for home use. We needed a low-cost, easy-to-use sensor that could empower consumers directly,” says Didar, Associate Professor and Canada Research Chair in Nano-biomaterials.

This technology can indicate to a consumer, in real-time, whether the product they’ve purchased or plan to purchase is fresh. “Consumers often prematurely dispose of food in the interest of safety. An assessment tool in their own hands can prevent food that’s fine to consume from making its way to the landfill,” he says.

Initial testing on fish showed strong correlation between colour change and pH levels, validating the sensor’s effectiveness, says Prasad. “The technology also remained stable under various humidity conditions, making it suitable for a wide range of storage environments and for rapid testing of open products.”

Phage fresh

Detection is one use for the McMaster-designed microneedle gelatin patches, but Hosseinidoust, Associate Professor, Chemical Engineering and Canada Research Chair in Bacteriophage Bioengineering (Tier 2), is focused on using similar technology for eliminating bacteria.

Loading the microneedle patches with phages to deliver antibacterial agents directly into food, especially moist, high-risk items like raw beef and ready-to-eat chicken can be achieved by the McMaster researchers without affecting taste or texture.

There’s tremendous potential for various applications of microneedle patches in food safety, and at McMaster, we’re on the brink of something game changing.

“Even in the face of concerns around antibiotic resistance, the food industry often turns to using antibacterial additives to address food contamination,” says Hosseinidoust, Associate Professor, Chemical Engineering and Canada Research Chair in Bacteriophage Bioengineering (Tier 2). “Phages are a promising alternative as they target bacteria in a highly specific manner.”

In fact, some tests in Hosseinidoust’s lab showed that E Coli and Salmonella were reduced to food industry-safe levels using phages via microneedle patch. The same phages were tested using a conventional, surface-level application and failed to decontaminate the food to the safe level, indicating the benefit of using the microneedles for phage diffusion.

“We have technology worth investing in to address serious food waste and security issues in Canada and across the world, but we need the will to adopt it,” says Hosseinidoust. “There’s tremendous potential for various applications of microneedle patches in food safety, and at McMaster, we’re on the brink of something game changing.”