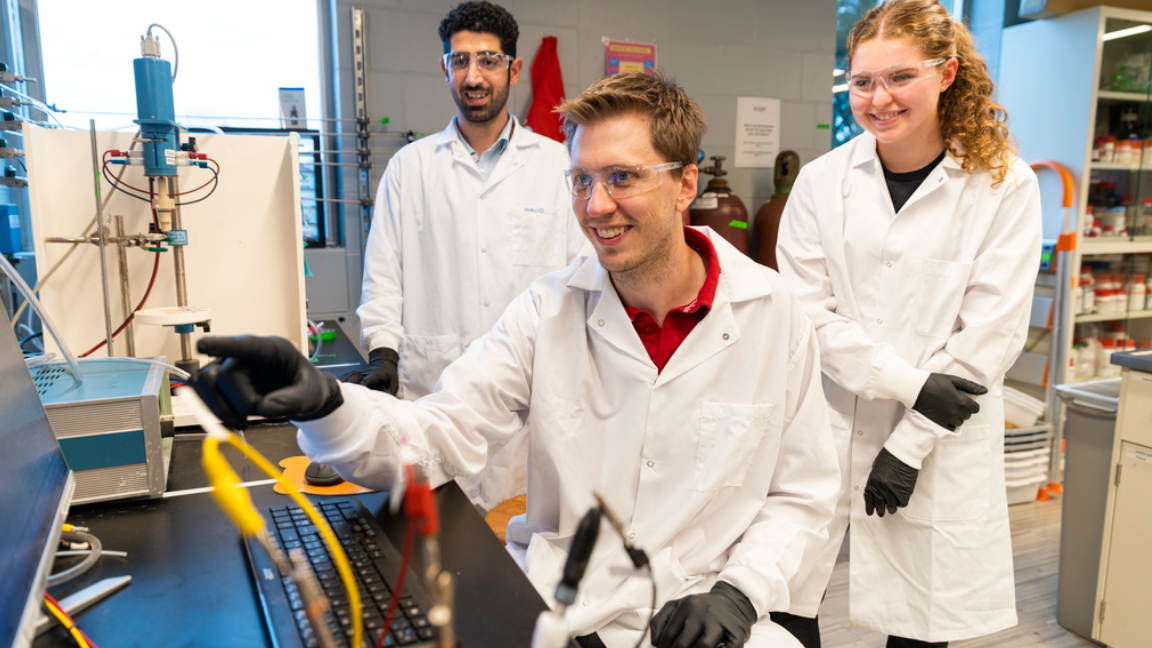

In the Higgins Lab at McMaster University, a team of researchers are tackling one of the planet’s most pressing challenges: how to turn harmful carbon dioxide (CO₂) into something useful; and do it affordably.

Led by chemical engineering associate professor Drew Higgins, the team has developed a promising new catalyst that could help industries reduce their carbon footprint by converting CO₂ into carbon monoxide (CO), a key ingredient in producing methanol and other industrial chemicals.

The innovation lies in a subtle tweak to existing materials. By adding microscopic particles of nickel zinc carbide to a nickel-nitrogen-carbon base, the researchers created a catalyst that’s not only highly efficient but also made from elements that are far more abundant and less expensive than traditional options like platinum or gold.

“We wanted something that was active, stable and scalable,” says Higgins. “Precious metals work well, but they’re not practical for widespread use. Our goal was to find a solution that could actually be implemented.”

But understanding why the new catalyst worked so well required a deeper look – one that went beyond the capabilities of their lab. That’s where PhD student Fatma Ismail stepped in, bringing the samples to the Canadian Light Source (CLS) synchrotron in Saskatchewan. There, the team used powerful X-rays to peer into the atomic structure of the material.

“The ultrabright X-rays at CLS allowed us to see how the atoms were arranged and how they interacted during the reaction,” Higgins explains. “It gave us insights we couldn’t get anywhere else.”

If we can show this works in real-world conditions, we could help industries turn a liability into an asset and take a meaningful step toward a more sustainable future.

What they found was surprising: the nickel played a more active role than expected, helping to drive the conversion process with remarkable efficiency. The discovery not only validated their approach but opened new doors for future research.

Now, the team is working to integrate the catalyst into prototype devices—systems that could one day be scaled up to industrial levels. The vision is bold: imagine factories outfitted with units that capture CO₂ emissions before they escape into the atmosphere, transforming them into valuable chemicals instead.

“If we can show this works in real-world conditions,” says Higgins, “we could help industries turn a liability into an asset and take a meaningful step toward a more sustainable future.”