When Saber Yu started McMaster’s Master of Engineering Systems and Technology program (MEST) in September 2024, he was eager to gain hands-on skills and real-world experience. Just eight months later, his industry-connected capstone project with Ascension Automation Solutions Ltd. led to a job offer as a Junior Computer Vision Engineer, all while still completing his degree.

Read a Q&A with Saber below to learn how he leveraged McMaster’s industry-connected MEST program to turn opportunity into employment.

What drew you to the MEST program at McMaster?

I compared McMaster’s MEST program with several other schools and found that it offered the best combination of hands-on learning with research and theory. Having completed my undergrad at McMaster, I also felt a strong connection to the school and knew it would be the right fit for me. The MEST program was actually the only program I applied to for my graduate studies.

How did your time at McMaster help prepare you for employment?

I came to this graduate program with a Bachelor of Engineering in Materials Engineering background and no prior work experience. My master’s program provided incredible opportunities for the students to learn and gain hands-on experience on AI, Computer Science and Automation. I have learned so much in the past eight months that ultimately led to my employment; this is at a rate I have never experienced before in my life.

Can you share more about the project you worked on with Ascension?

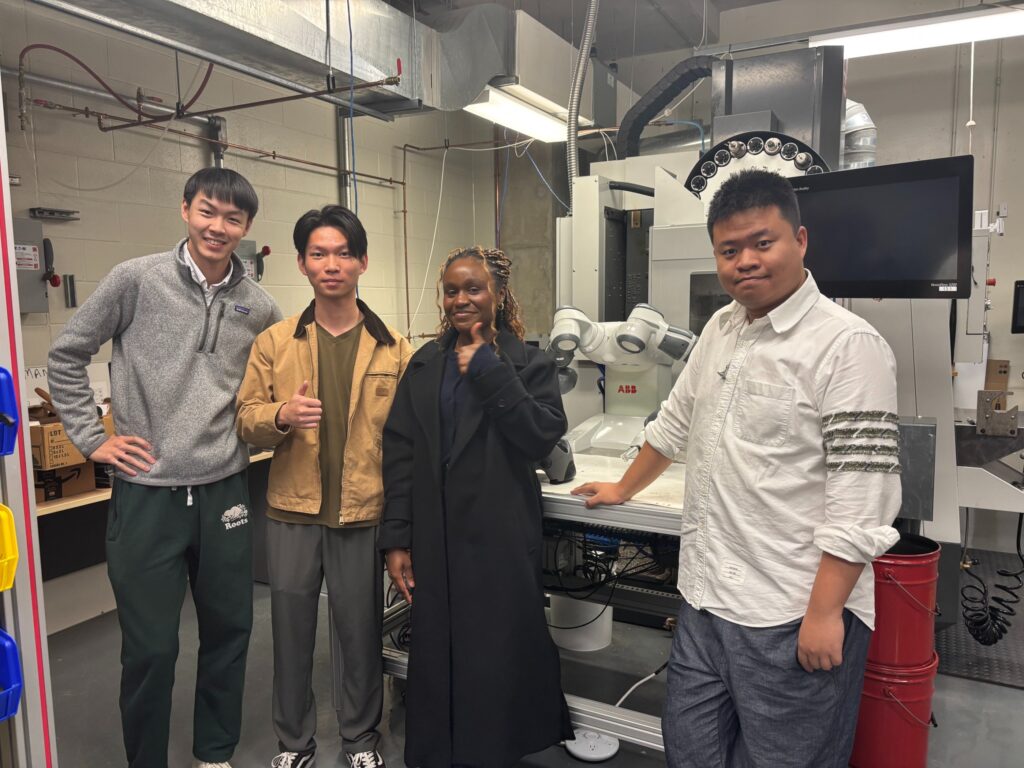

Our MEng project is about applying deep learning-based vision models on industrial defect detection applications. This is a collaboration between W Booth School faculty (Seshasai Srinivasa, Zhen Gao and Marjan Alavi), our industrial partner Ascension (particularly Tim Reinhart, Vision and R&D Manager), and two students (Mengchen Liu and myself).

During the project, we worked closely with Tim and conducted extensive research in domain-specific data augmentation techniques while also evaluating the performance of the latest state-of-the-art vision models, including CNN-based architectures and Detection Transformers. Our results offer excellent augmentation guidelines and model selection criteria for similar applications.

What was your reaction when you got the job offer?

I was very excited when I was offered the position of Junior Computer Vision Engineer. Ascension provides complete automation solutions to its customers and works on a diverse range of projects. I was excited about the opportunity to learn and work on innovative technologies with the team while applying the skills I learned at school on real-world applications.

What do you love most about working for Ascension?

We get to work on many different projects here at Ascension – vision guided assembly, defect detection for manufacturing, agriculture, nuclear, buildings, etc. Being able to work and learn on multiple projects across different industries is what I love most.

Any advice for future students interested in industry-connected projects?

The industry-connected projects are excellent for students without prior working experience in their fields as they provide opportunities for students to work on real-world problems with genuine industrial partners. My advice for future students is to stay self-motivated and self-driven as projects can sometimes face delays or unexpected challenges. Once the project is pushed through, the returns will definitely exceed one’s expectations.