What does an engineer do? The resounding response by the graduating students whose capstone projects were on display was: they innovate. Attendees marveled at their engineering feats that ranged from a Zamboni roomba to sustainable wound care.

“Such an inspiring day. Grateful to have had the opportunity to see the innovation these young, bright engineers have spent the year developing and testing.”

Around 150 alumni and industry partners attended, hanging out in a dedicated CapZone, and interacting with students who they may potentially work with in the future.

“If you’re ever feeling down about what is happening in the world, going to an event like this is a game changer. So many students have put so much time and effort into innovating and making inventions that can help make the world a better place.” – Shari van de Pol (‘01 Computer Engineering)

“Capstone is an integral part of the Mac Eng experience for our final-year students. They apply knowledge gained from the classroom, their co-ops, clubs and teams involvement, and other learning opportunities, into a project with tremendous potential for impact.” – Heather Sheardown, Dean

We caught up with five teams at the expo to learn more, in their own words, about their Made at Mac Eng projects, what they learned, and how they’re contributing to a brighter future.

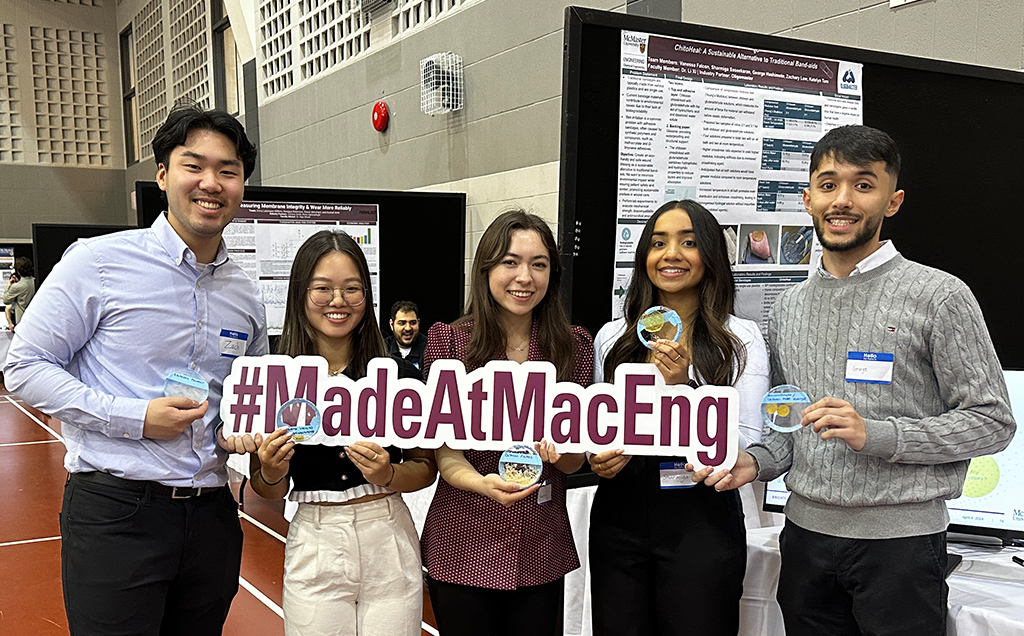

Sustainable Wound Dressing Alternative to Traditional Band-Aids (Chemical Engineering)

Team Members: Sharmiga Saseekaran, Katelyn Tam, Zachary Low, George Hashimoto, Vanessa Falcon

Instructor: Li Xi

Traditional bandages are made from different types of plastics and with the nature of their application, are always single use. Our goal was to provide an eco-friendly alternative to conventional band-aids, aiming to promote sustainable solutions, minimize environmental impacts throughout its lifecycle, all while prioritizing user safety and comfort.

We know that traditional band aids have acrylic based resins and the synthetic polymers that they’re made of can cause skin irritation, dermatitis, and allergic reactions, and that’s obviously not good. We’re hoping that our product that is derived from mushrooms can alleviate that. We are hoping to source these from vertical farms which enhances the sustainability of our product.

Getting to work on this Capstone project was a really unique experience just because of how five different group members came together, each with a different interest in chemical engineering and different strength and skills, to form a very complete product at the end.

Being able to work through projects with real life applications is a tremendous learning and collaborating with others and getting help from people who specialize in the field also really helped.

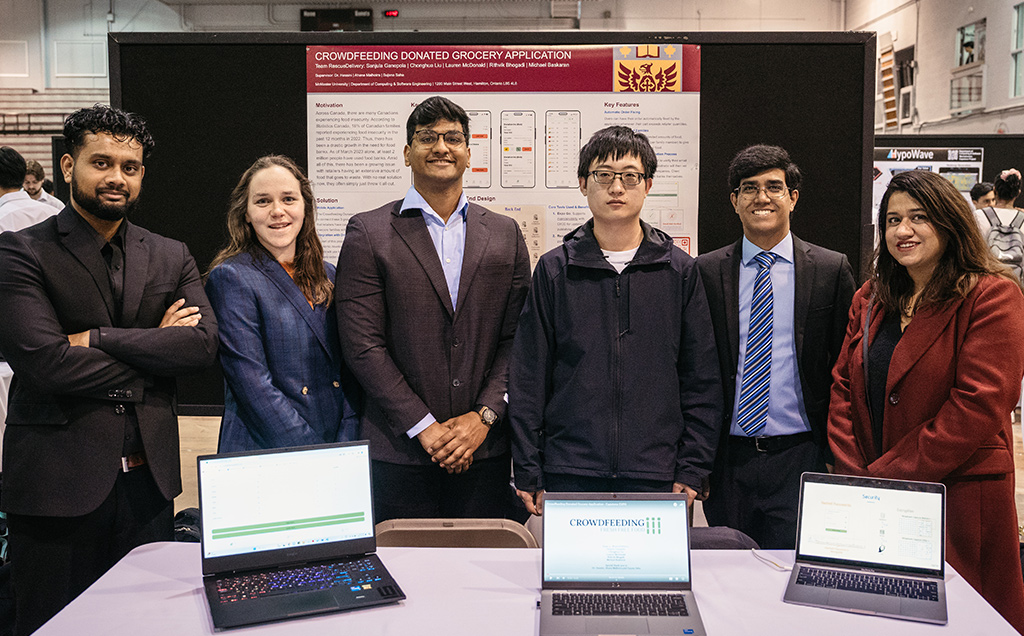

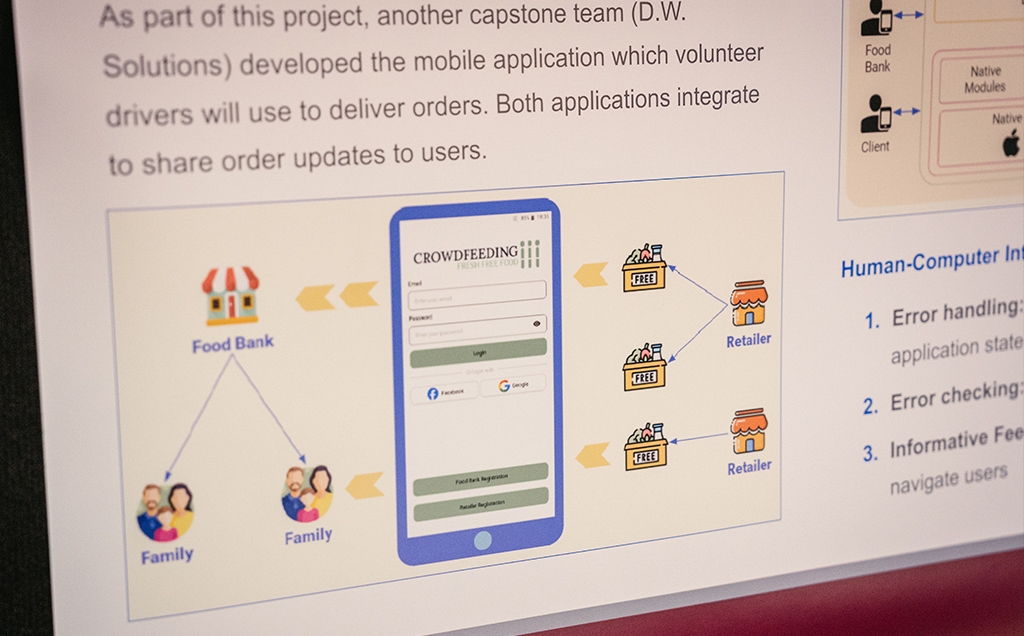

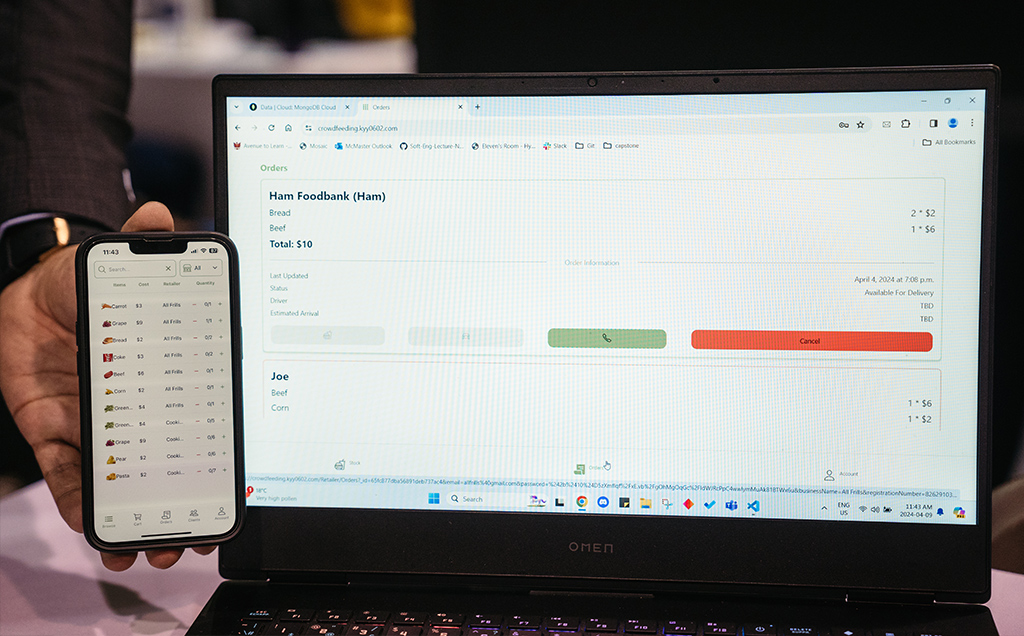

RescueDelivery: Food Rescue Using Micro Deliveries (Computing and Software)

Team members: Sanjula Ganepola, Rithvik Bhogadi, Chonghua Liu, Michael Baskaran, Lauren McDonald

Instructor: Spencer Smith

The Crowdfeeding Donated Grocery mobile application is a food ordering and delivery platform that aims to connect food banks and food insecure families with retailers who have excess food.

According to Food Waste Statistics, over 50 million tonnes of food is wasted every year in Canada and at the same time one in eight families are dealing with food insecurity. This application aims to tackle these issues by facilitating micro deliveries to aid with food rescue efforts. Beyond serving the complex network of non-profit food rescue organizations and charities, the application will also deliver directly to individuals and families facing hunger, fostering a better future, one meal at a time.

The culmination of this year long project is a fully-fledged product, equipped with all core features essential for facilitating micro deliveries while ensuring a seamless user experience. Although our Capstone has ended, the project is expected to continue as the development team and supervisors are committed to the mission.

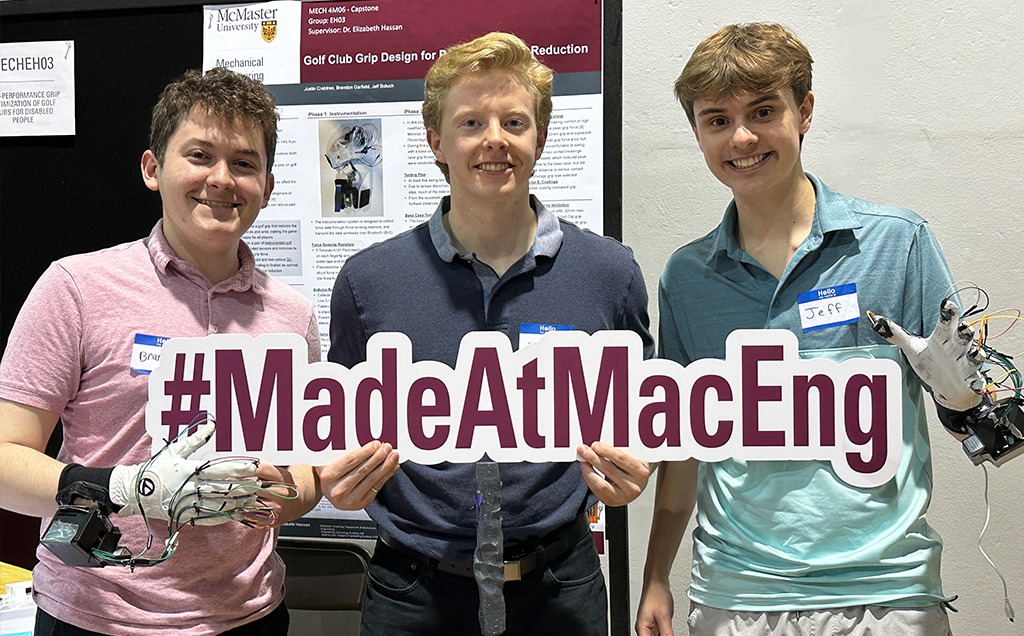

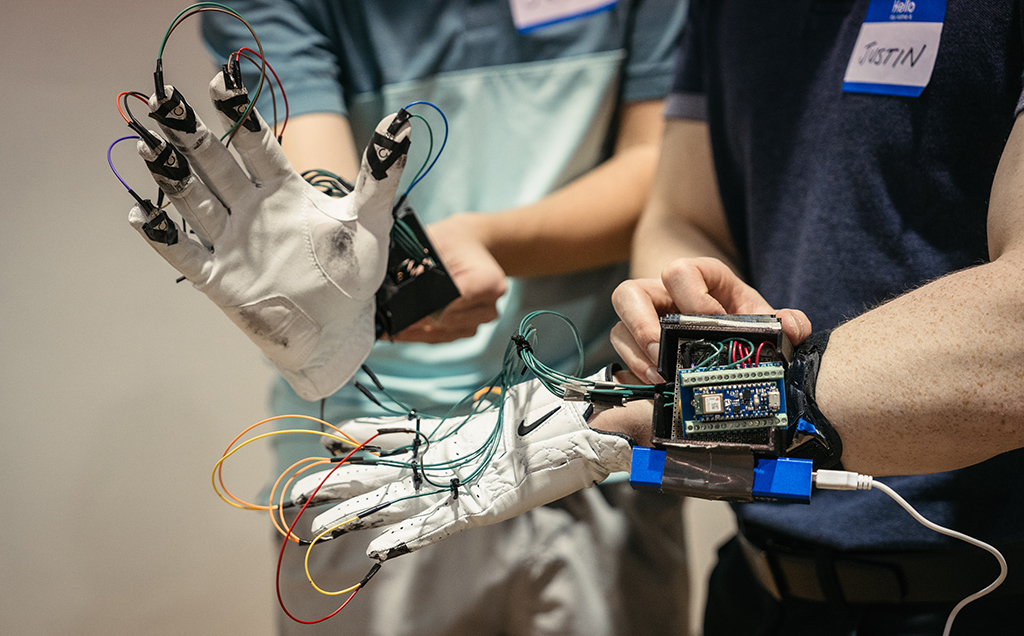

EH03 (Mechanical Engineering)

Team members: Jeff Boluch, Justin Crabtree, Brandon Garfield

Instructor: Elizabeth Hassan

We’ve created 3D-printed high-performance golf grips for people with wrist and hand-affecting disabilities, with the goal of reducing the strain on a golfer when hitting a golf ball. We developed a grip to reduce the peak grip force a person exerts, while also keeping the ball carry distance roughly the same as the person would hit with a regular golf grip.

It was an incredibly fun project to work on, and we learned so much about biomechanics, 3D printing, and force-sensing technology. Having the opportunity to work on a project that was both mechanical and electrical engineering-focused was a really fulfilling experience.

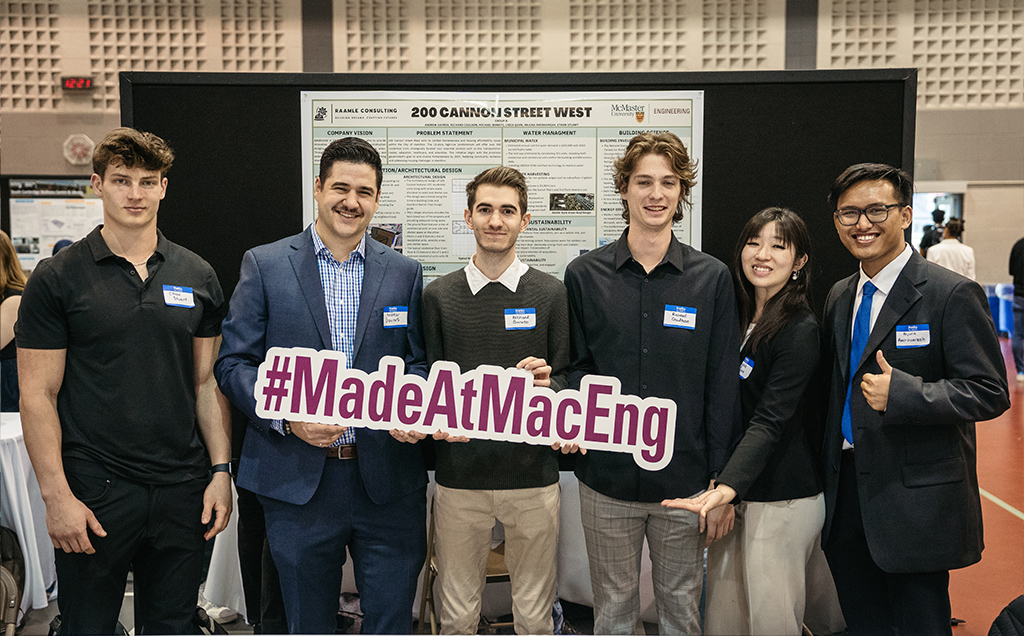

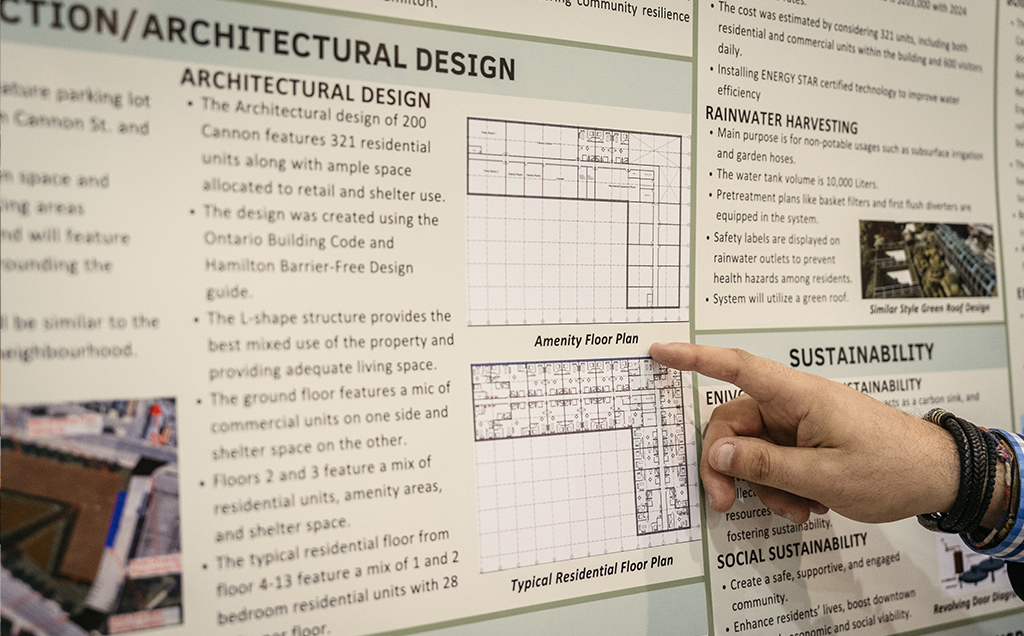

200 Cannon Street West (Civil Engineering)

Team members: Andrew Gavros, Arjuna Amirhamzah, Ethan Stuart, Lydia Hyunmi Quan, Richard Coulson, Michael Bonato

Instructors: Peijun Guo and Zoe Li

This project by RAAMLE Consulting seeks to address the urgent problem of homelessness and affordable housing within Hamilton and will rejuvenate the abandoned downtown location of Sir John A. McDonald Highschool.

We feel our project shows that a mixed-use development with both homelessness being tackled as well as affordable housing is something that could be implemented in the real world. We know especially within Southern Ontario, we’re so limited with space, so something like this can prove that social problems can be tackled in a new and innovative way.

Working on this project made us feel proud. We’re promoting ideas that will solve real problems that we’re seeing in our everyday lives. It’s something that we hope people can adopt, implement and make our everyday life better, but also make the lives of a lot of other people better based on it.

Impact of EV charging loads on electrical distribution systems (BTech)

Team members: David Cheriyan, Kehaan Baria, Yusuf Yusuf

Instructor: Chi Tang

Electric vehicle (EV) charging loads are expected to increase rapidly over the next few years. This project investigated their impact on existing power grids.

The impact of our project is that utilities will need information and analysis like this one to see how their infrastructure holds up for the future projected loads.

We tracked the charging station and figured out how much demand it is. Then we multiplied it by the speculated EV vehicle influx. We looked at all the scenarios, best case where everyone is charging at off-peak times, and worst case, at high peak times.

This probably isn’t the answer you’re looking for, but our calculations show that our existing power grids will be overloaded.

If you own an electric vehicle, we highly encourage you to charge in off peak hours (overnight)!

Photos by Geoff Shaw Photography

Check out more Capstone project features in the related stories below.