Innovative, collaborative, inspirational.

These attributes describe the projects four McMaster Faculty of Engineering students engaged in during their summer research term in the Learning Factory — a world-class, simulated factory environment on campus.

Designing a walking cane with smart technology and 3D-printed race car were part of the Engineering students’ summer research but have made such an impact, they’re being developed into ongoing work as student clubs.

Under the guidance of Learning Factory Director, Tom Wanyama, and B.Tech, Business and Management Program Chair, Hoda Kamel, the clubs will engage other students, benefit the wider community and foster business management skills, which are core to the B.Tech program.

Learn more about these impactful projects-turned-student clubs below.

Walking made smarter

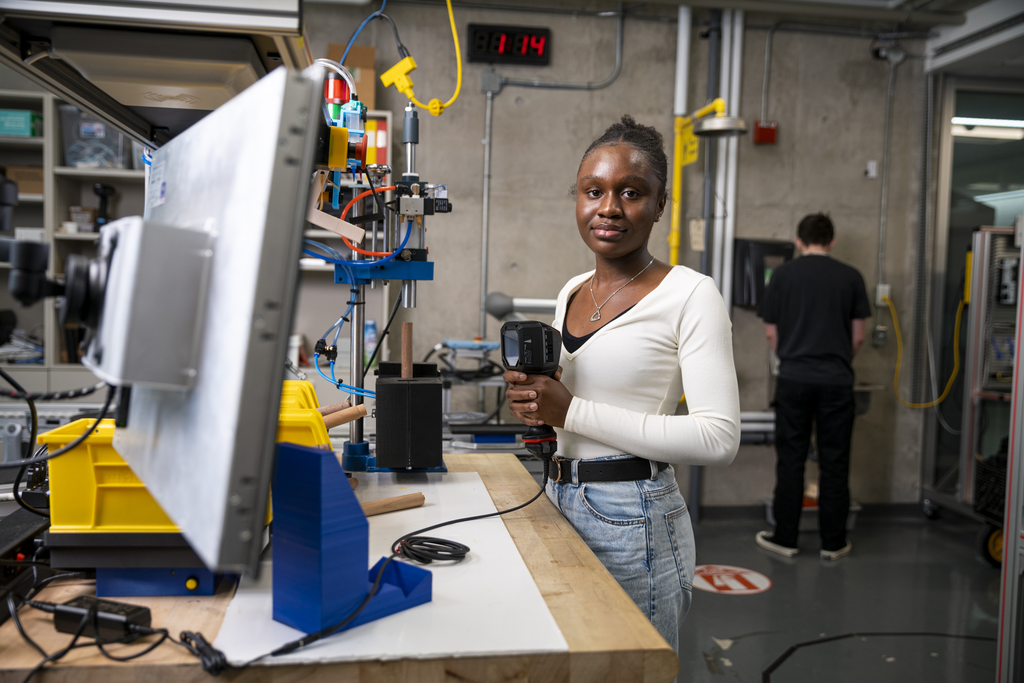

Third-year Automation Engineering student Onyinye Ugwuede is the team lead and creator of the Smart Systems Club. Its focus is to introduce students to the concept of production and integration of smart features into products for efficiency and functionality.

Ugwuede has been developing the Club’s first product, a walking cane.

“It’s a simple product by sight but has the ability to support people in their everyday lives,” says Ugwuede.

With the support of Wanyama, she plans to integrate smart features into the walking cane such as a pressure sensor that can display how much force someone is applying to the cane when walking. With this data, the team will be able to evaluate whether the cane user’s condition is improving or declining.

“With this device we can analyze data and compare the pattern of an individual who uses a walking cane with someone who does not,” explains Ugwuede. “This can be used to better treat individuals and improve quality of life.”

As work to integrate smart systems into the walking cane continues, marketing the cane has become a focus of Ugwuede’s fellow student researchers. From logo design, to packaging and website development, third-year B.Tech Automation Engineering students Tomasz Mizera and Sahil Patel teamed up with Ugwuede to establish a business selling the canes to generate funds to continue the project.

Working through challenges is part of the Learning Factory experience and the students faced their share bringing the cane to market.

“One of the most challenging parts was designing the packaging” explains Ugwuede. “Coming up with multiple designs to reduce cost but still satisfying the look we were going for, took the longest time.”

Patel, who created a Shopify website to market the walking cane, also encountered obstacles as he worked to get information from Shopify’s API and use it in Python.

“Creating a custom app within Shopify was time-consuming but crucial, he says. “It helped us store the API login details and decide what data we could access.”

The students persevered, drawing from business management skills they learned from Professor Kamel’s Fundamentals of Marketing class.

“The work we did very closely resembled course content,” says Mizera. “We were performing a real-world implementation of the theories taught there.”

Professor Kamel was impressed by the students’ application of learning in The Learning Factory.

“They engaged with internal and external parties at McMaster and deconstructed the project to understand the supply chain — a strategy used by profit-driven companies,” she explains. “They also obtained marketing permissions from the University and followed necessary steps to ensure product readiness for shipping.”

Racing to victory

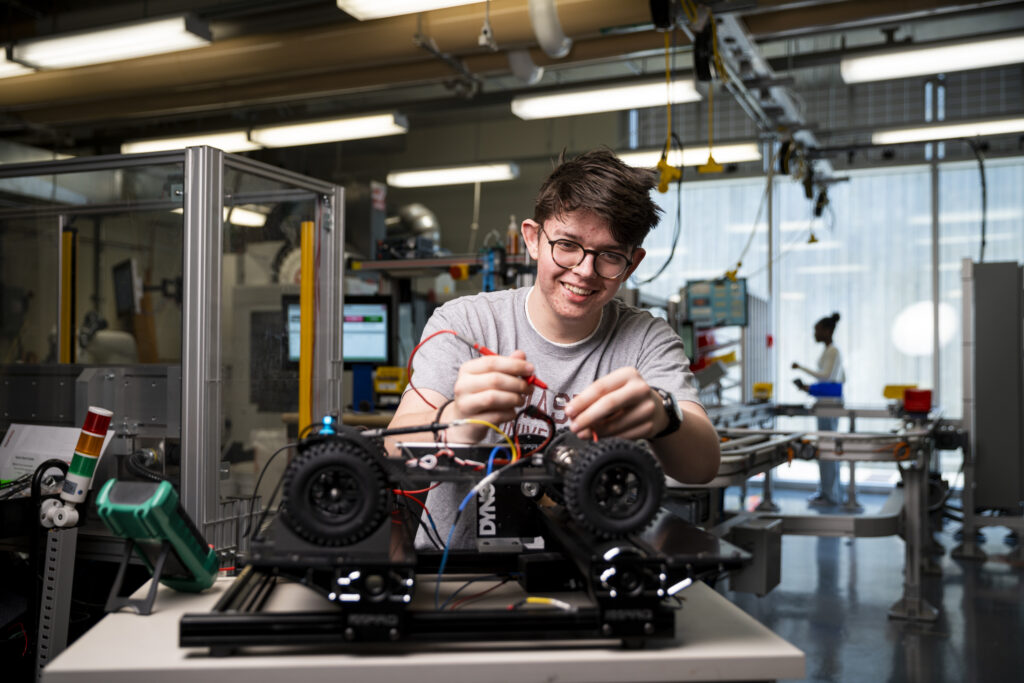

The Remote Controlled (RC) Car Club started by second-year Mechanical Engineering student Tyler Lounsbury aims to foster team building and collaboration amongst his peers.

He made a fully custom designed RC car that’s entirely 3D printed other than electronics and screws.

Students who join the club will partner up into smaller teams and purchase a DIY kit to assemble their own customizable RC car using the Learning Factory facilities.

“Not all parts will be provided in our kit, as we encourage teams to do some customization,” explains Lounsbury.

The club will also offer frequent tutorials and provide an environment where students can collaborate, share ideas and ask for help. Ultimately, the club plans to host competitions to race cars, an incentive for the students to put forward their best efforts when customizing their design.

Lounsbury also plans to partner with local high schools to provide DIY kits for design and technology classes.

“The car presents new opportunities for teaching and learning, and for outreach to high school students in science, technology, engineering, and mathematics (STEM),” says Wanyama.

Although summer is ending, the work continues into the new school new year. A few students have been rehired to pass on their skills to the incoming class. The Learning Factory will also sponsor the student clubs to ensure continuity of product development and improvement.

“Nothing is as rewarding as seeing the excitement among students after they learn a new concept or a new way of doing things through discovery,” says Wanyama. “We had a countless number of such moments this summer.”